Working principle

The material enters the dryer from the feeding port, and under the action of excitation force and hot air, the material is thrown along the horizontal bed surface, jumping forward to promote material fluidization. After passing through the fluidized bed, the hot air undergoes sufficient heat exchange with the wet material, and the humid air is discharged through the fan after being dedusted by the cyclone separator. The dried material is discharged through the discharge port.

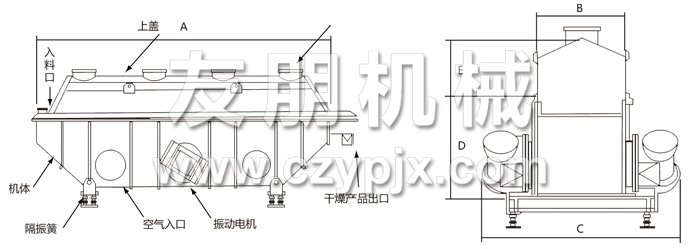

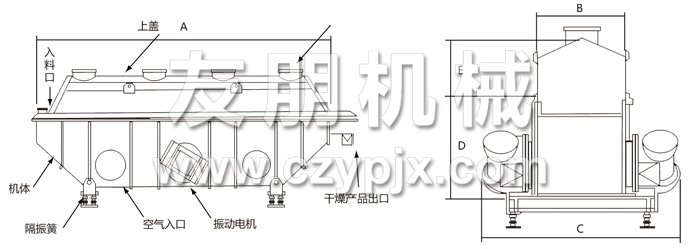

Structural schematic diagram

Adaptability to Materials

Suitable for drying or cooling operations of powdery and granular materials in industries such as chemical, pharmaceutical, food, grain, and minerals. Examples include: citric acid, monosodium glutamate (MSG), borax, ammonium sulfate, compound fertilizers, carrots, soybean meal, distillers' grains, seeds, slag, sucrose, etc.

Performance Features

• The vibration source is driven by a vibration motor, which ensures smooth operation, convenient maintenance, low noise, and long lifespan.

• Uniform fluidization, no dead spots or blow-through phenomena, resulting in uniform drying or cooling products.

• Good adjustability and wide applicability. The thickness of the material layer, internal movement speed, and full amplitude can all be infinitely adjusted.

• Minimal surface damage to the material. Suitable for drying fragile materials, and irregular particle shapes do not affect the working efficiency.

• The structure is fully enclosed. Effectively prevents cross-contamination between materials and air, ensuring a clean working environment.

• High mechanical and thermal efficiency, with good energy-saving effects, saving 30-60% compared to general drying equipment.

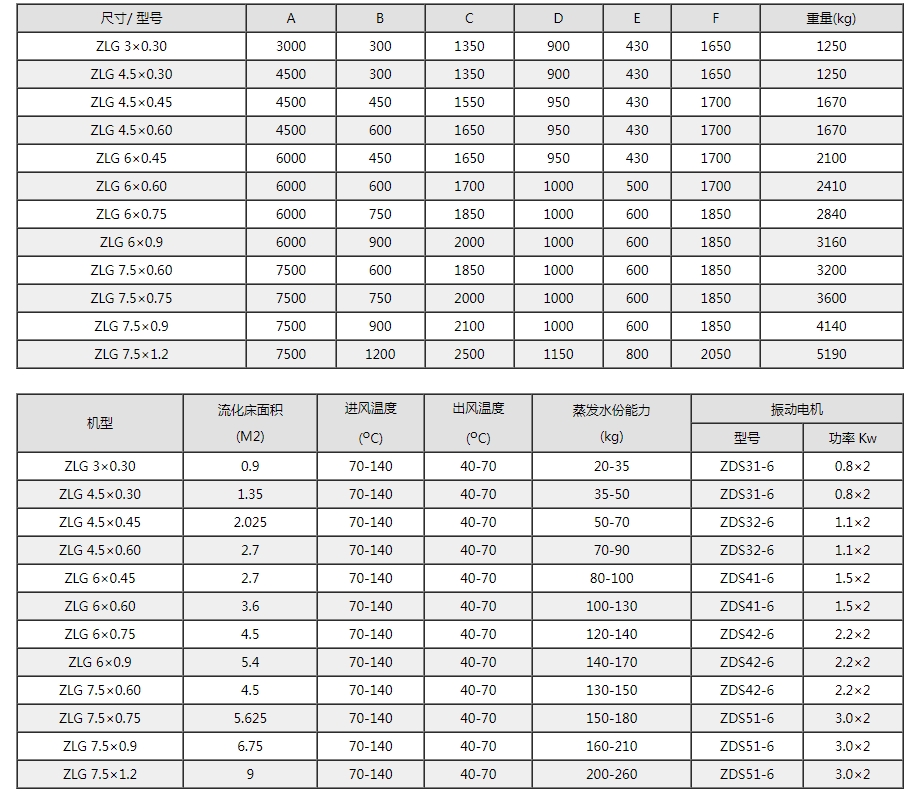

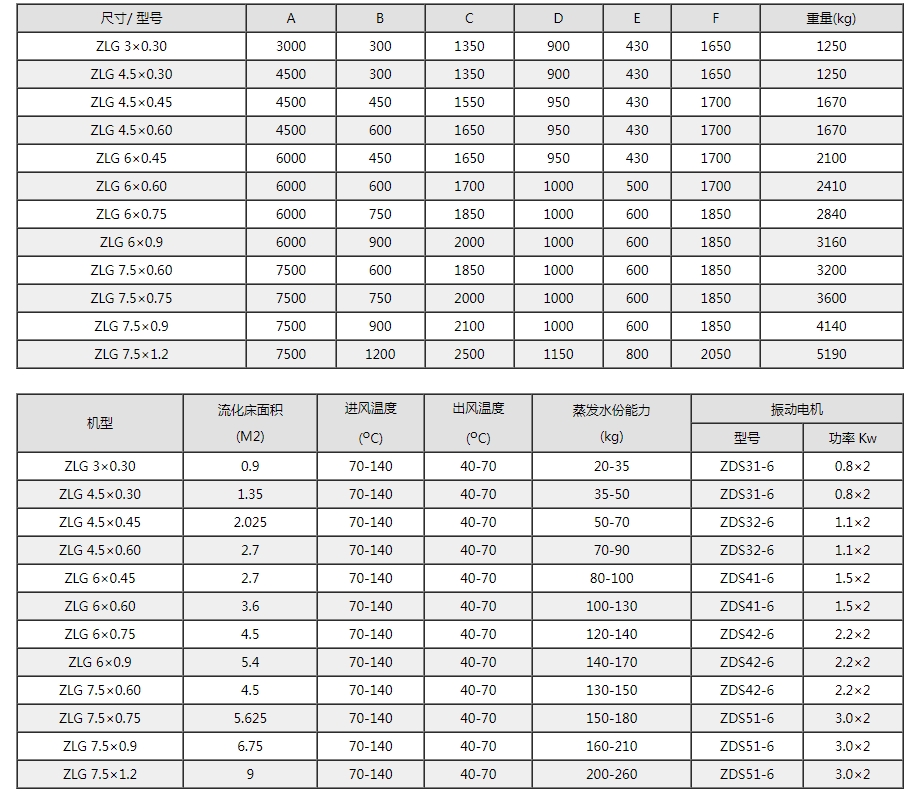

Technical specifications

The above evaporation rate is the highest evaporation rate.

Hot Tags:

Vibrating Fluidized Bed Dryer Fluidized Bed Dryer ZLG Series Fluidized Bed Dryer