szhzzkgzj01b

szhzzkgzj03b

201812041243482911

201812041243483535

201812041244026899

1/

SZG Series Double Cone Rotary Vacuum Dryer

The double cone rotary vacuum dryer is an intermittently sealed drying equipment. During operation, the material is added into a closed container, and a heat source (such as hot water, low-pressure steam, or heat transfer oil) is introduced into the jacket of the container. The heat is conducted through the walls to heat the material. As the container is under vacuum conditions, the operating pressure drop causes the moisture (solvent) on the surface of the material to reach a saturated state and evaporate. The wet vapor is promptly expelled or recovered by a vacuum pump. The internal moisture of the material...

Product Overview

The SZG double-cone vacuum dryer is a new generation of vacuum drying equipment developed by our company, integrating domestic similar products. The double-cone vacuum dryer adopts a belt-chain dual-elastic connection method, making the equipment operation more stable. Professional design processes fully ensure that the two shafts are perfectly concentric. The heat medium inlet and outlet, as well as the vacuum exhaust system, use reliable mechanical seals or rotary joints with American technology. The machine can be infinitely variable speed and can also be temperature controlled.

As a professional manufacturer of drying equipment, this product can use various heat sources such as high-temperature heat transfer oil, medium-temperature steam, and low-temperature hot water. If drying viscous materials, a special "scoop plate" can be designed inside the tank or ball bearings can be set.

Working Principle

-

A heat source (such as hot water, low-pressure steam, or heat transfer oil) is introduced into the sealed jacket, and the heat is conducted through the walls to the material being dried.

-

Driven by power, the tank rotates slowly, and the material inside the tank is continuously mixed and heated and dried under vacuum conditions, thereby strengthening the drying process.

-

The material is in a vacuum state, and the operating pressure drop causes the moisture (solvent) on the surface of the material to reach a saturated state and evaporate quickly. The wet vapor is promptly extracted or recovered by a vacuum pump. The internal moisture (solvent) of the material continuously permeates, evaporates, and is expelled, allowing the material to dry in a very short time.

Adaptability

-

Suitable for the concentration, mixing, and drying of powdery, granular, and fibrous materials in industries such as chemical, pharmaceutical, and food, as well as materials that require low-temperature drying (such as biochemical products). It is more suitable for drying materials that are easily oxidized, volatile, thermolabile, strongly irritating, toxic, and materials whose crystalline structure must not be destroyed.

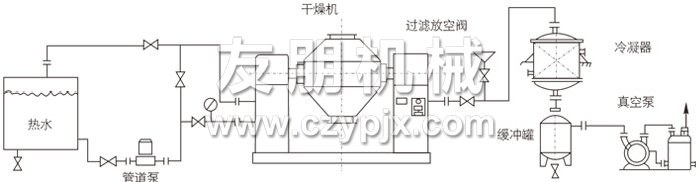

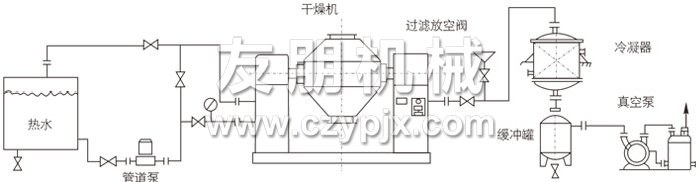

Installation Demonstration

Performance Features

-

When oil heating, automatic temperature control is used, which can dry biochemical products.

-

For mineral raw materials, the temperature can be between 20~160°C.

-

High thermal efficiency, more than double that of a general oven.

-

Indirect heating ensures the material is not contaminated, meeting "GMP" requirements. The equipment is easy to maintain and clean.

-

Recommended process layout demonstration, solvent recovery process layout.

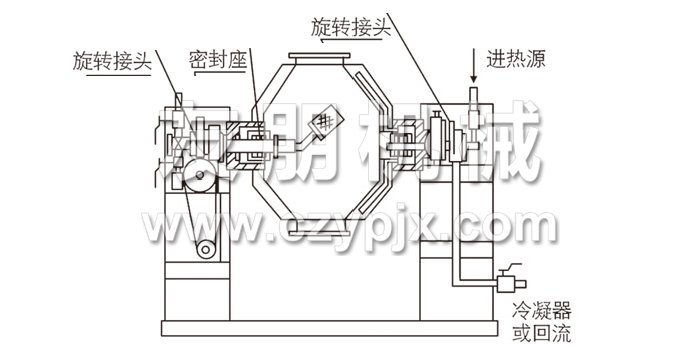

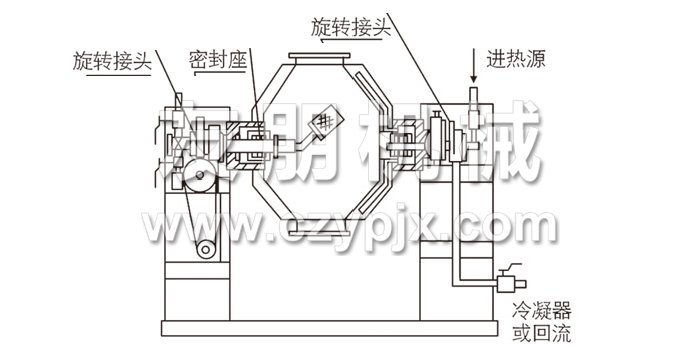

Structural Schematic Diagram

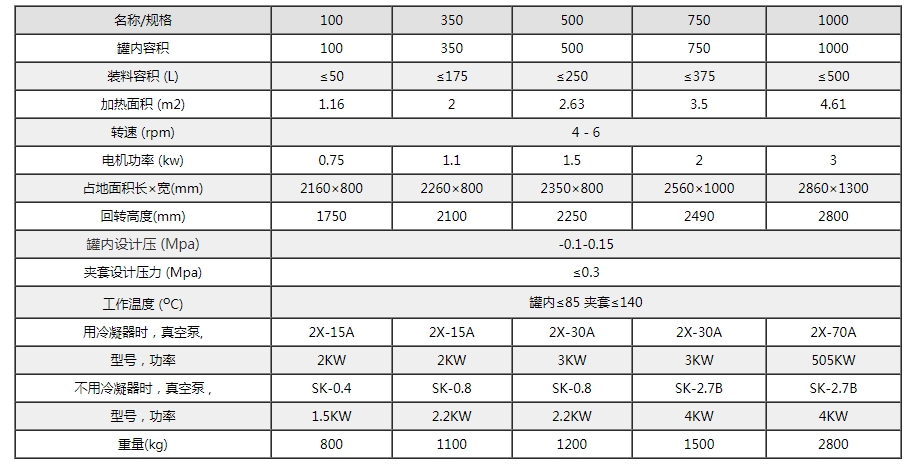

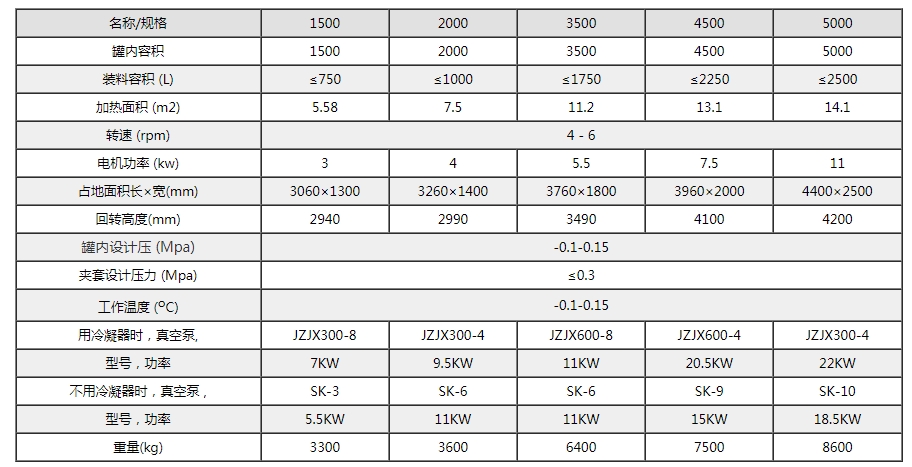

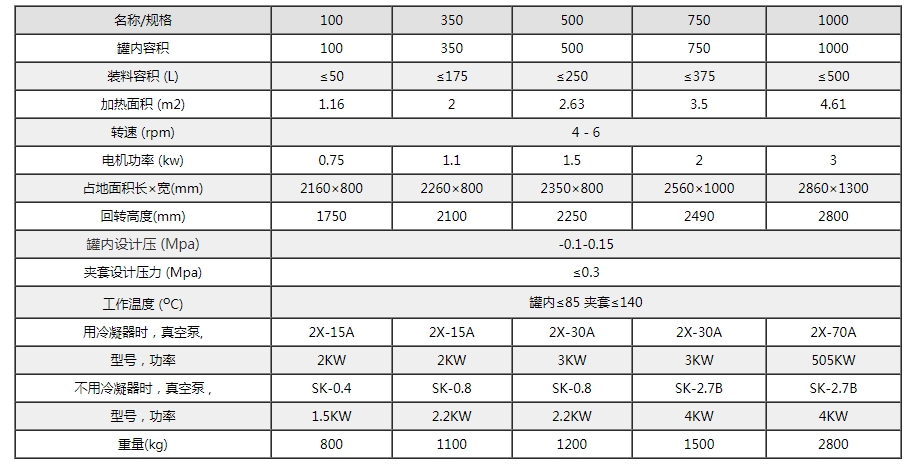

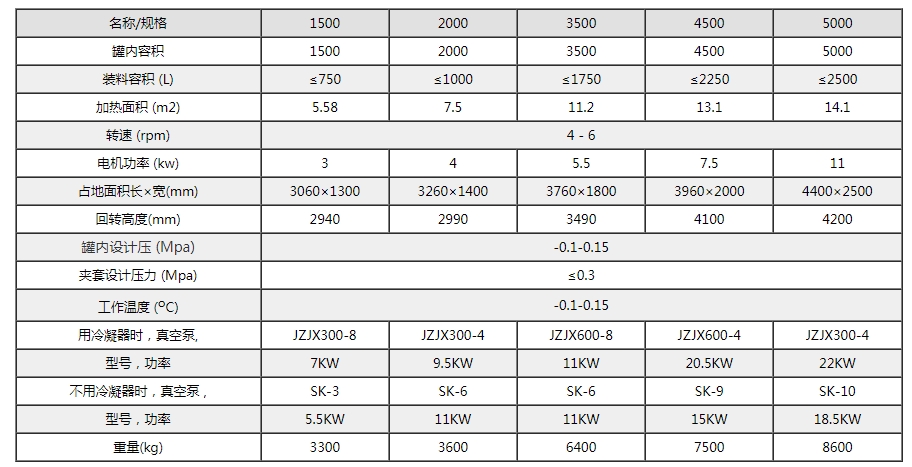

Note: For materials with significant volume changes before and after drying, the loading coefficient can be appropriately increased or decreased.

Hot Tags:

Double Cone Rotary Vacuum Dryer Double Cone Vacuum Dryer Rotary Vacuum Dryer