- Under vacuum conditions, the boiling point of the material solution is reduced, and the driving force for heat transfer during water evaporation is increased. Therefore, a certain amount of heat transfer can save the heat transfer area of the evaporator.

- The heat source for water evaporation operations can use low-pressure steam or waste steam.

- The evaporator has minimal heat loss.

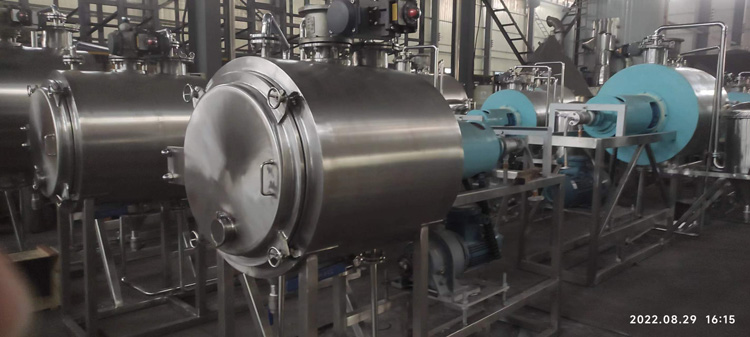

- Sterilization treatment can be performed before drying, and no impurities enter during the drying process, meeting GMP requirements.

- As it is a static vacuum dryer, the shape of the dried material will not be damaged.

- Suitable for low-temperature drying of heat-sensitive materials that are prone to decomposition, polymerization, or deterioration at high temperatures, widely used in the pharmaceutical, chemical, food, and electronics industries.

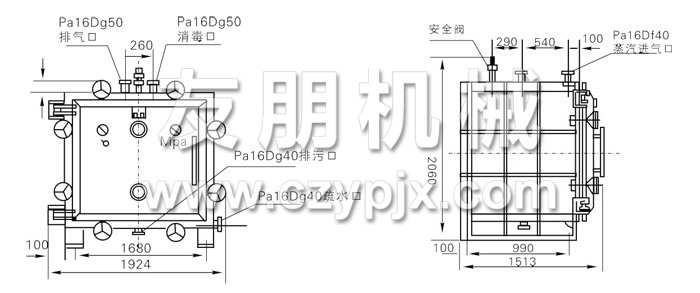

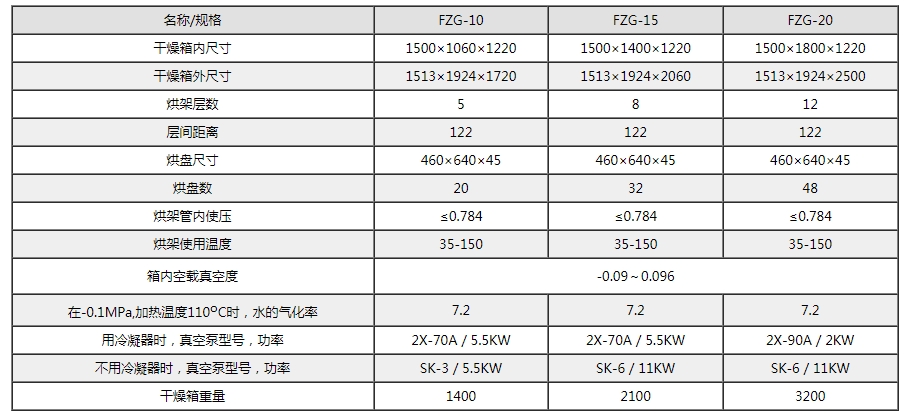

- When placing an order, please select the appropriate vacuum dryer based on factors such as the initial and final moisture content of the drying material, temperature, vacuum degree, drying quantity, and drying time. The same model of vacuum dryer is available with four heating methods: steam, hot water, heat transfer oil, and electric heating. For example, to increase the drying capacity, you can appropriately increase the number of drying racks, please inform our factory in a timely manner.

- Our factory can provide and install accessories for the vacuum drying system mentioned in the user manual. Please specify when placing an order.

- Our company can provide design, manufacturing, and installation for special requirements in the vacuum drying system proposed by the user.

- Our company implements a quality assurance policy for all our equipment. We will provide all accessories on a long-term basis, so please rest assured.

Hot Tags: Rectangular Vacuum Dryer Rectangular Vacuum Oven FZG Type Vacuum Oven