This dryer uses high-pressure dry air to atomize the material and spray it onto the surface of a boiling medium (inert particles). The material is subjected to dual heat transfer from hot air and the medium, resulting in a low internal pressure. Water molecules quickly diffuse and escape, and drying can be achieved within seconds (depending on the characteristics of the material); At the same time, there was intense media movement, and the surface film was peeled off and crushed, then discharged with hot air and collected through a collection system. The media particles reach the upper part of the spray tower, the wind speed decreases and they settle freely, and then they are covered by the material mist again, starting a new round of drying process. The whole drying process is operated continuously, the drying time is short, and the material properties are basically unchanged, which can meet the quality index requirements. At the same time, it solves the problems that are difficult to solve, such as poor atomization and wall sticking, when high viscosity materials are dried by spray.

The inert particles in the fluidized bed can play a role in dispersing and grinding materials, dispersing and fluidized paste like or solution like materials that cannot be fluidized, enhancing heat and mass transfer, fast material drying speed, high thermal efficiency, and directly obtaining granular materials without screening or crushing. Inert particles with a diameter of 1~5mm, such as glass beads, ceramic balls, steel balls, etc., are often used as streaming media.

Inert particle fluidized bed drying can replace spray drying in many occasions, and is suitable for drying solution materials. Compared with spray drying, it has higher drying intensity and can be dried with lower heat source temperature (such as low-pressure steam, waste hot water, etc.); Under the same conditions, the equipment scale is much smaller (its volume is generally only about 10% of that of the spray drying tower), the system floor area and height are significantly reduced, the equipment investment is correspondingly reduced, and the system energy consumption is also significantly reduced.

2、 Equipment features

1. High degree of fluidization, uniform heating of materials, and sufficient heat exchange;

2. Compact structure, small footprint, high evaporation intensity per unit volume;

3. Continuous operation, able to adapt to large-scale production;

4. Wide adaptability, can be widely applied in industries such as traditional Chinese and Western medicine, chemical industry, food additives, etc., meeting GMP requirements;

5. When the solvent is an organic solvent, an inert gas closed-loop circulation method can be used to achieve solvent recovery while the material is dry.

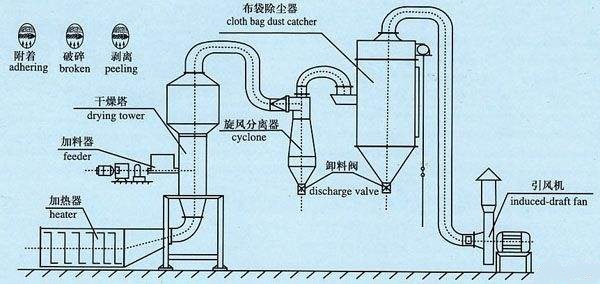

3、 Working principle

The feed liquid to be dried is sent to the spray tower through the feed liquid delivery pump, and is atomized by heated compressed air to cover the surface of inert particles (media) in boiling state, forming a film coating layer. At the same time, it is subject to the double heat transfer of hot air and media, and its water evaporates rapidly and is dried. Due to intense media movement, the dried material coating is crushed into powder products due to collision, which are discharged with hot air and captured in the cyclone separator. The exhaust gas then enters the bag filter and is filtered again before being discharged.

According to the characteristics such as melting point and viscosity of the material, suitable control temperature, media particle size, and material can be selected. If necessary, hollow particles can be chosen as the drying medium. According to the characteristics of the material, pulse bag dust collectors or wet spray dust collectors can be selected as secondary dust removal equipment. Choose steam, electric, or hot air stoves as heat sources based on user conditions and the temperature that the materials can withstand.

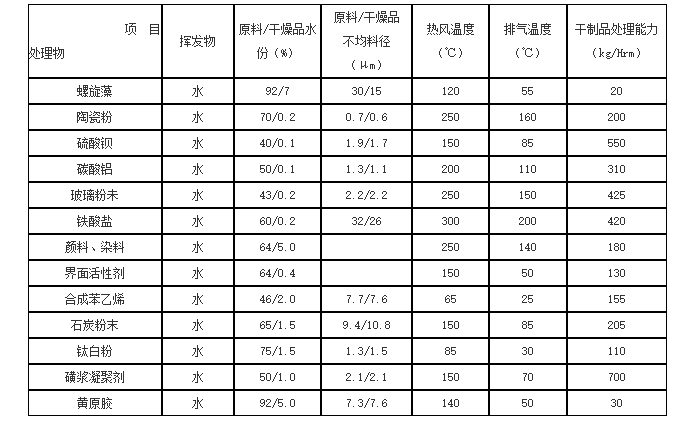

This process is suitable for drying various solutions, suspensions, emulsions, paste materials, thin paste materials, filter cake materials, such as dyes, pigments, coatings, agricultural chemicals, biochemical products, soybean milk (flour making), humic acid, Chinese herbal extracts, pesticides, lignin, pectinase, etc.

Typical dry materials: iron oxide red, iron oxide yellow, iron oxide black, fermentation powder, diatomaceous earth, titanium dioxide, starch, sulfide iron brown, calcium carbonate, sodium nitrite, humic acid, barium sulfate, aluminum carbonate, scarlet acid, traditional Chinese medicine extract, concrete water reducer, potato slurry.

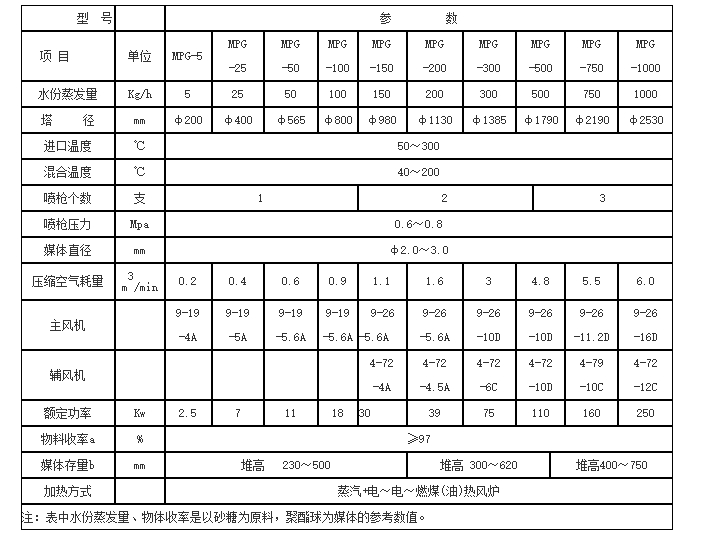

5、 Technical parameters

Hot Tags: Inert Particle Fluidized Bed Drying Machine Particle Fluidized Bed Drying Machine Fluidized Bed Drying Machine