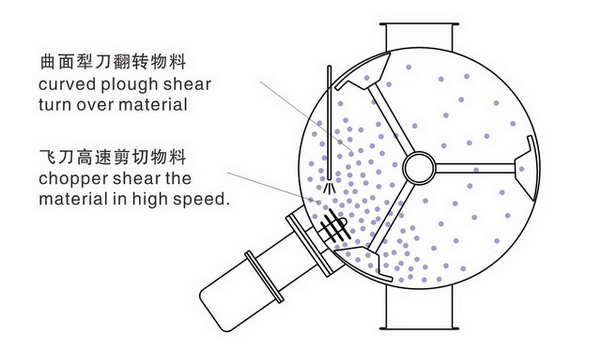

The plow blade mixer is a single axis forced mixing device, with multiple sets of plow blade agitators installed on the main shaft and continuously installed in a staggered manner. When working, the plow blade agitator moves in a circular motion, and the material is divided into two directions by the plow blade surface. It crosses and diffuses with the material diverted from the adjacent plow blades, forming an uninterrupted vortex centrifugal material flow. The vortex centrifugal material flow continuously overlaps and disperses, and when it flows through the high-speed flying blade, it is sheared and scattered by the blade blades, causing the material to boil and achieving the effect of rapid mixing.

The combination of plow blade agitator and high-speed flying blade can quickly disperse, cut and separate materials, making it more suitable for mixing materials that are prone to clumping, viscous, easy to clump when adding liquid, have poor flowability, and low viscosity fluids.

The high-speed flying knife is installed at a 45 degree angle downwards on the side of the mixer cylinder. The blade head extends into the cylinder, and the material is driven to the effective range of the flying knife by the plow blade. It is quickly sheared and scattered by the flying knife, and mixed quickly.

The total height of the equipment is only half of that of a vertical mixer of the same specification, which can reduce the height of the factory and is more suitable for direct connection with other equipment, reducing the equipment footprint.

More device configuration methods can be used for multiple purposes, better meeting customer needs.

Extended functionality

Add liquid - increase spray and cleaning system.

◆ Add a jacket - can be filled with hot water, thermal oil or steam to heat the material, achieving drying and mixing for multiple purposes.

Vacuum operation - The equipment can be designed for vacuum operation and can vacuum suction materials.

◆ Load start protection device - hydraulic coupling.

Speed: Single speed, dual speed, variable frequency speed regulation or stepless speed regulation can be selected.

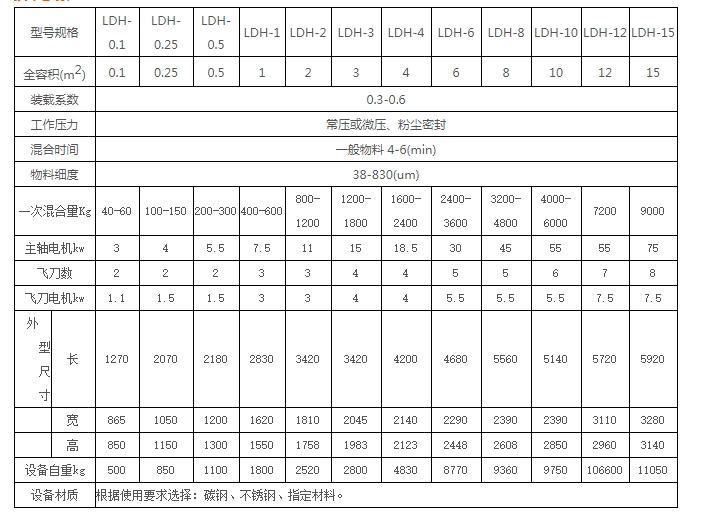

Technical parameter

Selection method

The equipment is a batch mixer, and the corresponding specifications of equipment are selected based

on the processing capacity or material volume of each batch within the specified range.

◆ Select equipment materials, which are determined based on factors such as material properties,

operating conditions, and hygiene levels. There are various conventional materials such as carbon steel

and 304/316L/321 stainless steel. After selecting the material, determine the surface treatment method

according to the requirements of the process.

The driving power of the equipment configuration is determined based on the proportion of materials,

mixing amount, and starting method. The starting form can be divided into heavy-duty starting and no-load starting.

Based on actual process requirements, add auxiliary functional components such as spraying, heating, or cooling.

Equipment opening design requirements, such as feeding port, cleaning port, exhaust hole, etc.

◆ Choose the discharge mode, which can be butterfly valve, ball valve, flap valve, star discharge valve, or knife gate valve.

The driving form can be manual, pneumatic, or electric.

Hot Tags: plow blade mixer LDH series paddle mixer LDH series soil mixer