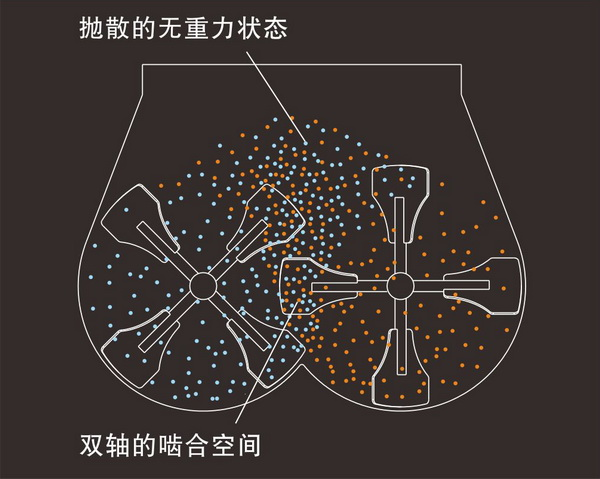

The gravity free mixer consists of a W-shaped cylinder, a double blade mixing shaft, and a transmission mechanism. During operation, the dual axis reverse rotation drives the blades at different angles on the shaft to circulate and flip the material in the axial and radial directions. The material is thrown up by the blades at a higher linear velocity and is in a weightless (i.e. gravity free) state before falling down. Through continuous throwing up and down, the material is mixed evenly across the shaft. And it can be equipped with a crushing rod to increase the crushing function, which can partially crush granular materials.

2、 Equipment features

1. The mixing effect is very high. This machine is a high-precision mixer. Even if there are significant differences in the specific gravity, particle size, and ratio of the materials, the mixing blades arranged in a staggered manner can quickly and violently churn and sprinkle, achieving good mixing effects.

2. Crushing device. When materials have clumping and agglomeration phenomena, it is necessary to add a crushing device. A "crushing rod" with a triangular tooth cover should maintain a speed of over 1000rpm to crush and depolymerize the clumped materials in the weight loss zone.

3. Discharge form. Pneumatic flap valves are generally used for discharge, with circular arc valves tightly embedded in the cylinder, flush with the inner wall of the cylinder, and no material accumulation or mixing dead corners; There are often two types of discharge doors: large and small. The large door opens to the edge of the cylinder, allowing for clean and efficient discharge with minimal residue.

4. Two piece blade. To reduce the cost of replacing vulnerable parts of the equipment, the blade blades can be made into two pieces, and a movable small blade can be placed on the blade base to directly replace worn small blades, which is economical and fast.

5. Direct connected reducer. For large mixers with a capacity of 6 cubic meters or more, in order to increase torque and reduce maintenance rates, a direct coupled gear reducer is used, which effectively solves some of the previous defects.

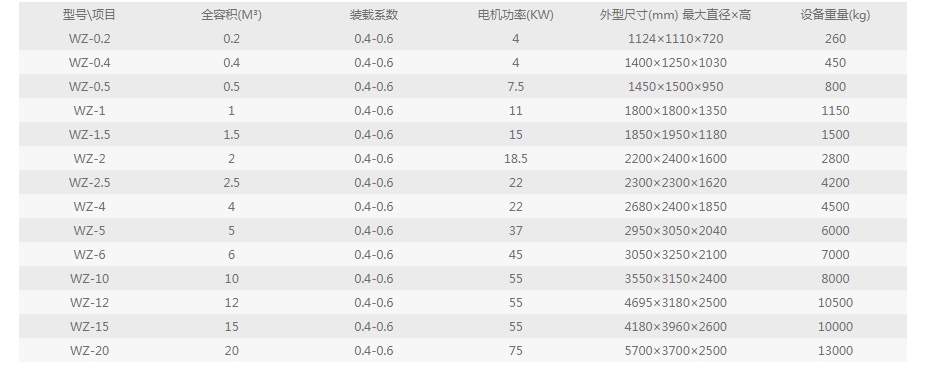

3、 Technical parameters

4、 Application scope

The gravity free mixer is suitable for mixing powders with powders, particles with particles, particles with powders, and adding small amounts of liquid. It is widely used in industries such as chemical, dry powder mortar, pesticides, ceramics, food, feed, and batteries. This machine is a high-precision mixing equipment with wide adaptability to mixtures. It can mix materials with large differences in specific gravity, ratio, and particle size evenly, and can mix materials with ratio differences of 1:1000 to 10000 or even higher well.

Hot Tags: WZ series conical screw mixer WZ series gravity discharge mixer WZ series low-intensity mixer