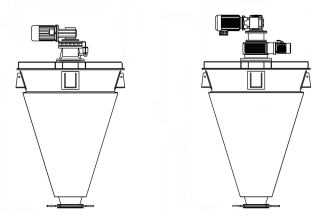

The DSH double helix cone mixer is a new type of high-efficiency mixing equipment improved from the single helix cantilever cone mixer. The machine can be controlled by one (or two) sets of motors and reducers for self rotation and revolution, and adopts asymmetric mixing with two screws. The material mixing range is large and the mixing speed is fast. This machine is suitable for mixing materials such as powders, powders, and liquids added to powders. It has strong adaptability to mixtures, and does not produce overheating when mixing thermosensitive materials. Granular materials will not be compressed or ground, and materials with significant weight differences and mixing ratios will not experience delamination or segregation.

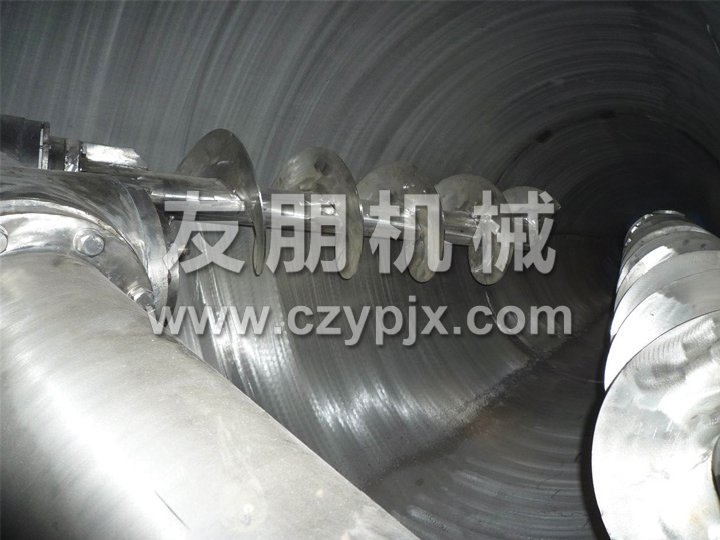

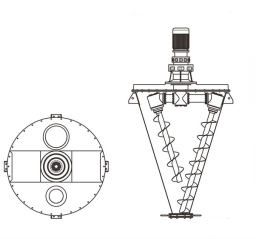

The rotation and revolution of the stirring spiral cause the material to undergo composite motion within the cone, resulting in the following four forms of motion:

1. The spiral revolves around the conical wall, causing the material to move in a circular motion along the conical wall;

2. Spiral rotation causes the material to spiral upwards from the bottom of the cone, lifting the material;

3. Spiral self revolution and compound revolution motion, where a portion of the material is absorbed into the spiral cylindrical surface, while being subjected to the centrifugal force of the spiral rotation, a portion of the material in the spiral cylindrical surface is discharged radially towards the cone;

4. The lifted material descends due to its own gravity.

The coexistence of four types of motion generates convection, shear, and diffusion effects on the material, thereby achieving rapid and uniform mixing.

3、 Equipment features

1. Thoroughly discharge materials without residue, meeting high standard discharge requirements.

2. The stirring method is gentle and will not damage the crystal state, making it suitable for mixing fragile materials.

3. Low energy consumption, good mixing effect, and wide applicability to materials.

4. Flying knives and spray atomization devices can be installed to meet special process requirements.

5. Equipped with a spherical discharge valve, the discharge is more thorough and stable.

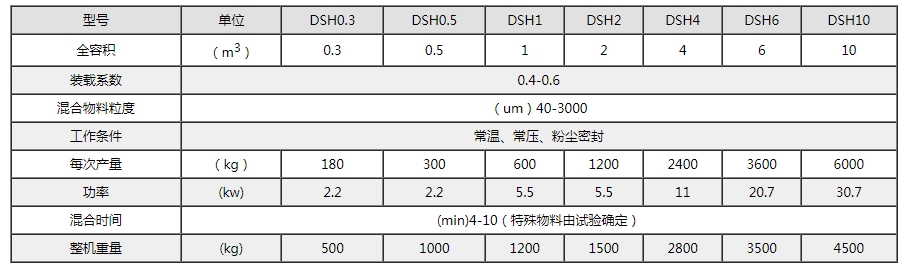

4、 Technical parameters

1. Determine the volume of each batch of mixed materials, ranging from 0.1-20 cubic meters, and select equipment of the corresponding specifications.

2. The selection of equipment materials mainly distinguishes the material requirements for the parts in contact with the materials and the parts not in contact with the materials, while keeping the original materials for other components of the equipment. Conventional materials include carbon steel, 304/316L/321 stainless steel, etc. The surface treatment requirements are determined based on factors such as material properties, working conditions, and hygiene levels.

3. Configure the driving power based on the characteristics of material density, fluidity, and equipment start-up requirements. The equipment startup requirements are divided into heavy-duty startup and no-load startup.

4. According to the process requirements, add corresponding supporting auxiliary functions such as liquid spraying, heating/cooling, etc.

5. According to actual operation and usage requirements, design the opening requirements of the equipment, such as feeding port, cleaning port, exhaust hole, etc.

6. Select the discharge mode and driving method, including manual, pneumatic, and electric.

Hot Tags: double helix cone mixer Spiral Cone Mixer DSH double helix cone mixer