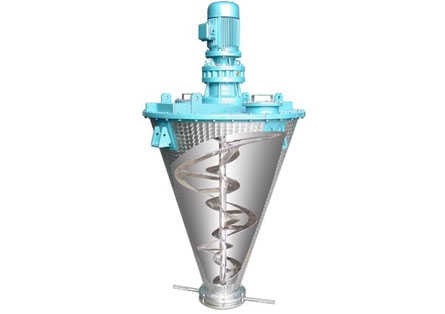

The LDSH series conical spiral belt mixer consists of a conical cylinder, a stirring device, and a transmission mechanism. The stirring device includes a central spiral shaft and a stirring spiral belt that is tightly attached to the inner wall of the cylinder. This machine is suitable for mixing powders and granular materials with high hygiene requirements, as well as for mixing materials with viscous fluids or materials mainly composed of thick, wet, and paste. Widely used in chemical, pesticide, dye, pharmaceutical, feed, fertilizer, metallurgy, mining

Working principle

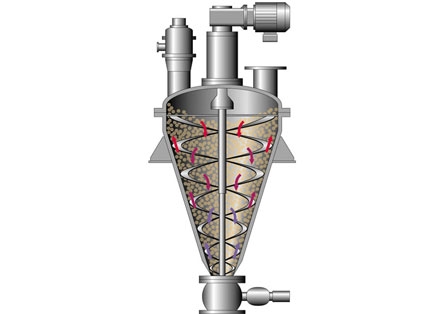

The stirring device of a conical spiral belt mixer is usually composed of a central spiral shaft and two outer spiral belts that match the inner wall surface of the cylinder. When rotating, the outer spiral belt spirals upwards along the inner wall of the cylinder to lift the material. Due to the different linear velocities at various points on the surface of the spiral belt, the material undergoes irregular convection, shear, mixing, and diffusion under its action, forming a comprehensive composite motion. The spiral blades on the mixing shaft lift and throw out the central material during operation. Part of the thrown out material enters the spiral belt, and at the same time, the part of the material thrown out by the spiral belt is absorbed into the spiral envelope of the spiral blades and lifted. Repeat this process repeatedly to achieve uniform mixing of materials in a short period of time.

Equipment features

Suitable for mixing powders, granular materials, slurries, or viscous substances, with a wide range of applications.

◆ Strong mixing effect, the wall attached spiral belt and inner spiral simultaneously lift or compress the material, forming a cyclonic material flow, suitable for mixing powder or slurry materials with poor fluidity.

The mixing process is relatively gentle, does not damage the material particles, and has low fragmentation.

The discharge is clean, and almost all materials can be discharged.

Structure characteristics

The reducer directly drives the mixing device to rotate, ensuring smooth operation, compact structure, and small footprint;

There is no transmission mechanism inside the cylinder to prevent material contamination caused by lubricant leakage;

The gap between the outer screw and the container wall is very small, which can prevent material adhesion;

Internal surface treatment of equipment to eliminate dead corners.

Additional (Extended) Function

According to the process requirements, it can be professionally designed and manufactured according to positive pressure or vacuum state standards;

Equipped with a jacket or coil, it meets multiple functions such as mixing, stirring, vacuum drying, etc;

The cylinder cover is designed in the form of a head structure according to user requirements, which is pressure resistant and aesthetically pleasing;

◆ Multiple sealing device options: standard packing seal, skeleton seal, mechanical seal

Discharge valve: plum blossom displacement valve, ball valve, butterfly valve, gate valve available for selection;

Install a spray device and equip it with CIP online rotating cleaning spray balls for equipment cleaning;

Add a shredding device that can crush polymers to meet process requirements.

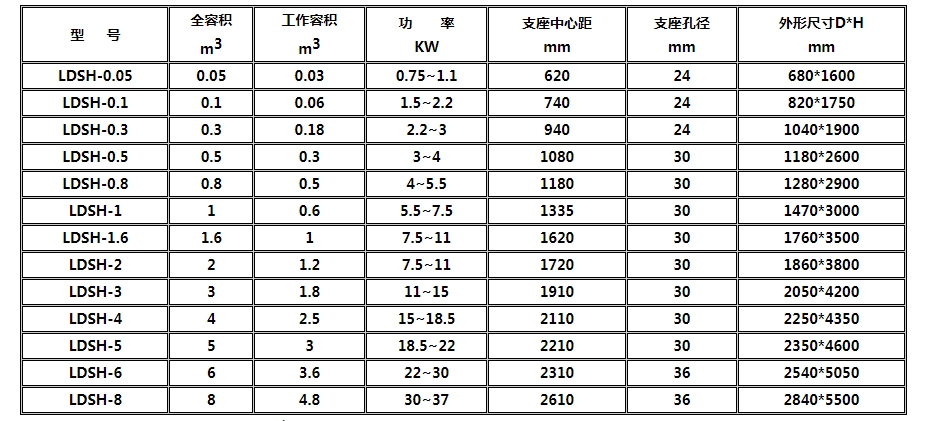

Technical parameter

Note: 1. Due to updates to this device, technical parameters may be changed without prior notice.

The correct parameters are subject to the actual product provided,

2. If there are special processes such as high temperature, high pressure, high viscosity, explosive,

flammable, and corrosive, relevant parameters must be provided for professional customization.

Hot Tags: Conical spiral belt mixer Spiral belt mixer LDSH series Spiral belt mixer