Working Principle

So-called vacuum drying is the process of drying materials under vacuum conditions by applying heat. Utilizing a vacuum pump to extract air and moisture can accelerate the drying speed. If a condenser is added to the vacuum system, solvents from the materials can be recovered through the condenser; if the solvent is water, a condenser is not needed, saving on equipment investment.

Performance Features

1. Under vacuum conditions, the boiling point of the material solution is reduced, and the driving force for water evaporation is increased. Therefore, with a certain amount of heat transfer, the heat transfer area of the evaporator can be saved.

2. The heat source for water evaporation operations can use low-pressure steam or waste heat steam.

3. The evaporator has minimal heat loss.

4. Sterilization treatment can be performed before drying, and no impurities enter during the drying process, meeting GMP requirements.

5. As it is a static vacuum dryer, the shape of the dried material will not be damaged.

Adaptability to Materials

Suitable for low-temperature drying of heat-sensitive materials that are prone to decomposition, polymerization, or deterioration at high temperatures, widely used in the pharmaceutical, chemical, food, and electronics industries.

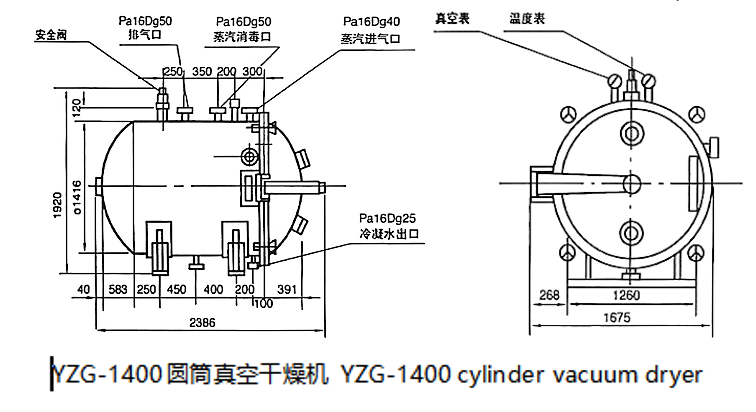

Structural Schematic Diagram

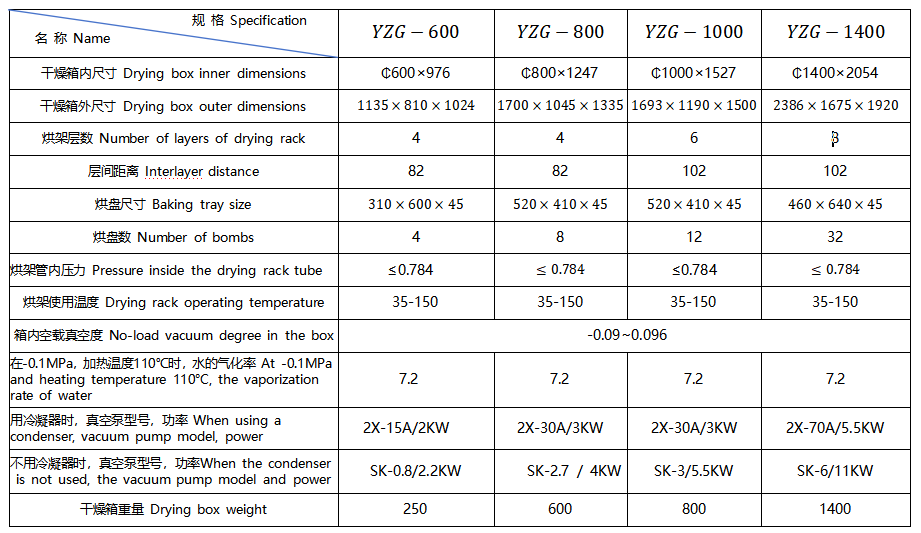

Technical Specifications

Note: A water ring vacuum pump is used in conjunction with mechanical boosting to enhance the vacuum level.

Hot Tags:

Circular vacuum oven Circular vacuum drying oven Circular vacuum Dryer