Fluidized bed drying machine

-

XF series horizontal boiling dryerBoiling drying, also known as fluidized bed drying, mainly consists of an air filter, heater, boiling bed main unit, cyclone separator, bag dust collector, high-pressure centrifugal fan, and control panel. Depending on the nature of the raw materials, dust removal equipment can be配套 used. Cyclone separators and bag dust collectors can be selected for dust removal, or one of them can be used alone.read more

-

ZLG series vibrating fluidized bed dryerThe vibrating fluidized bed dryer generates excitation force through the vibration source, making the material easier to fluidize. The material enters the dryer, and under the action of vibration force and hot air, the material is thrown up and jumps forward along the surface of the fluidized bed. The hot air passes through the fluidized bed to fully exchange heat with the moist material. Then it is dusted by a cyclone separator or bag dust collector and then discharged by an exhaust fan. The dried material is discharged from the discharge port at the other end of the fluidized bed. This machine is suitable for powder drying in chemical, pharmaceutical, food processing, grain, mineral and other industries.read more

-

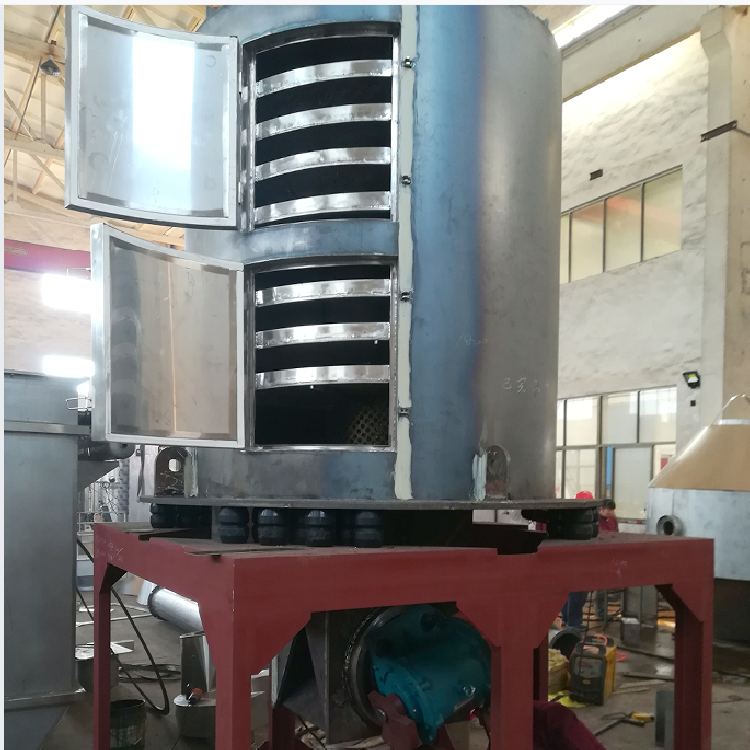

LZG series spiral vibration dryerDrying method of spiral vibrating dryer: Wet materials enter the spiral bed from the top feeding port. Under the action of circumferential exciting force and gravity, the materials jump down along the spiral bed from top to bottom until they reach the bottom layer. Meanwhile, clean hot air enters from the bottom of the spiral bed, undergoes sufficient heat and mass transfer with the raw materials distributed on the bed, and then is discharged through the top moisture exhaust port, thus achieving the purpose of material drying.read more

-

GFG high-efficiency boiling dryerThe working principle of the GFG series high-efficiency boiling dryer is as follows: After the air is purified and heated, it is drawn into the bottom of the hopper by an induced draft fan and passes through the bottom grid plate of the hopper. In the working chamber, fluidization is formed through stirring and negative pressure. Moisture evaporates quickly and is discharged, thereby enabling rapid drying of the material.read more