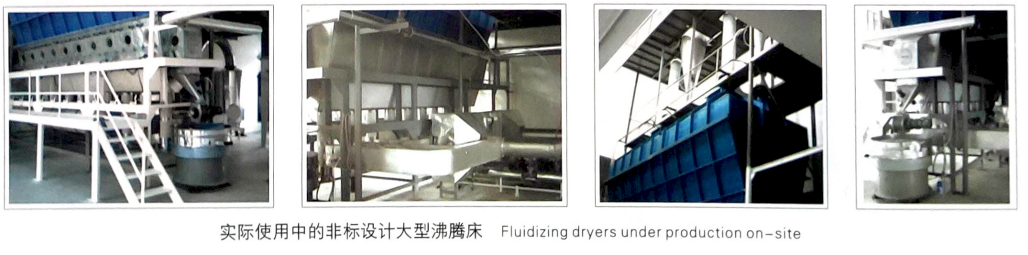

Equipment overview

Fluidized bed drying, also known as fluidized bed drying, mainly consists of air filters, heaters, fluidized bed dryers, cyclone separators, bag dust collectors, high-pressure centrifugal blowers, control panels and other components. Due to the different properties of dry materials, the corresponding dust removal equipment can be selected according to needs. Cyclone separator and bag dust collector can be used at the same time or separately. Generally speaking, for granular or granular dry materials with a larger specific gravity, it is sufficient to use a cyclone separator alone; for small particles and powdery materials with a small specific gravity, a bag dust collector is required. The system is equipped with belt conveyors or pneumatic feeding devices to achieve automated operation.

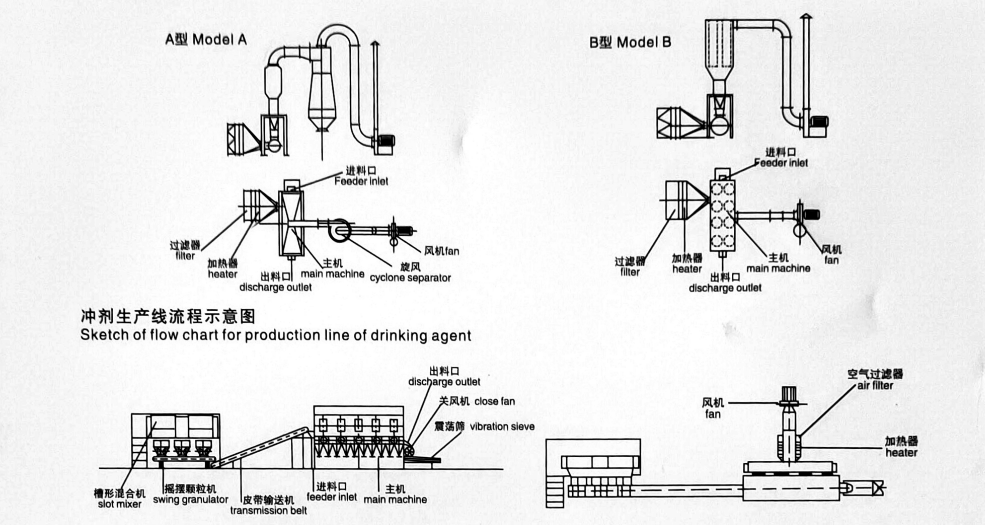

The granular solid materials are fed into the fluidized bed dryer through the feeder. The blower sends the filtered clean air to the bottom of the fluidized bed after being heated by the heater. The air passes through the distribution plate and contacts the solid material to form a fluidized state, thereby achieving heat and mass transfer between the gas and the solid. The dried material is discharged from the discharge port. After the waste gas passes through a cyclone dust collector or bag dust collector to recover solid powder, it is discharged from the top of the fluidized bed.working principle

The clean air is heated by the heater and enters the fluidized bed through the bed air distribution plate. At the same time, the wet material is sent to the dryer from one end of the fluidized bed through the feeder, and the wet material is boiled by the hot air on the fluidized bed. Due to the extensive contact between hot air and materials, the heat and mass transfer processes between the two are strengthened, so drying can be achieved in a relatively short time. Generally, continuous operation is adopted. The material enters from one end of the bed, boils and dries for a few seconds to a few minutes, and then is automatically discharged from the other end of the bed. The device generally works under negative pressure.

Application areas

This machine is applicable for drying operations in industries such as pharmaceuticals, chemical raw materials, food processing, grain processing, and feed. For example: medicines, tablet granules, traditional Chinese medicine granules, health foods, beverage granules, corn germ, feed, plastic resins, citric acid, and other powdered materials. The suitable raw material particle size is generally 0.1-6mm, with a preferred particle size of 0.5-3mm.

Structural schematic diagram

Installation requirements

◆ The dryer should be placed horizontally and fixed with base bolts, and all components should be well sealed.

◆ The fan can be placed outdoors or in a homemade soundproof room, and the layout can be adjusted according to specific conditions.

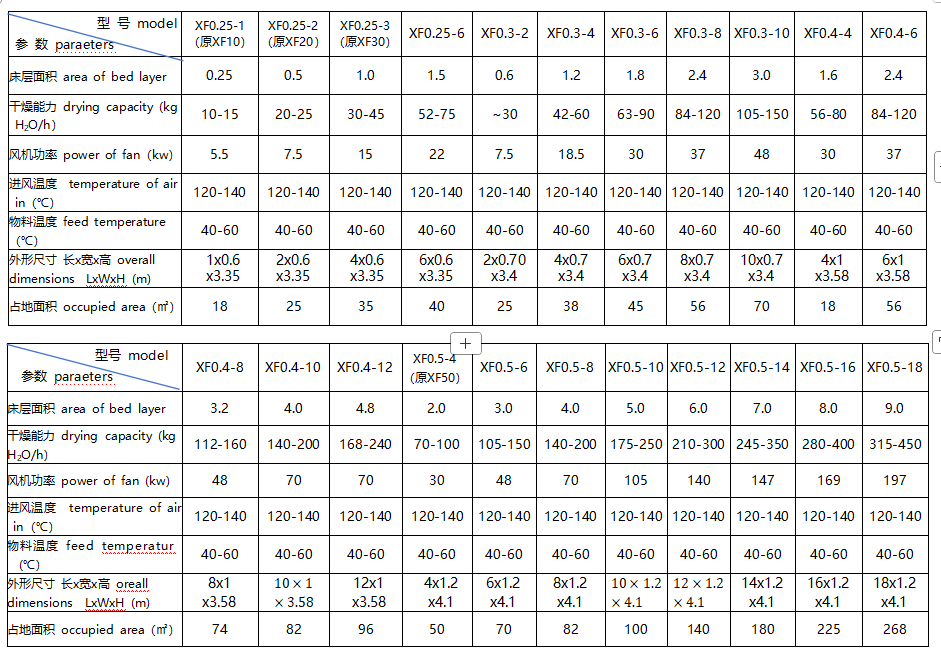

Technical Specifications

Hot Tags: Horizontal boiling dryer Horizontal fluidized bed dryer Fluidized bed drying machine