The CT-C series hot air circulation oven is equipped with a low-noise and high-temperature resistant axial flow fan and an automatic temperature control system. The entire circulation system is fully enclosed, which increases the thermal efficiency of the oven from the traditional drying room 3-7% to the current 35-45%, and the high thermal efficiency can reach 50%. The successful design of CT-C type hot air circulation oven has enabled China's hot air circulation oven to reach domestic and international standards.

view more

Changzhou Youpeng Machinery Co., Ltd

Our factory has over 20 years of experience in manufacturing equipment, with eight technical experienced R & D engineers and fifty-five skilled workers. We have introduced several sets of advanced production equipment, and digestion and absorption of advanced production technology, successfully acquired a number of patents, can provide customers with better service and products. The workshop area is over 6000 square meter; the office area is over 2000 square meter. And factory has certificated by BV, SGS, TUV and GMC. Factory production system have certificated by ISO9001-2008 & ISO14001-2004.

read more

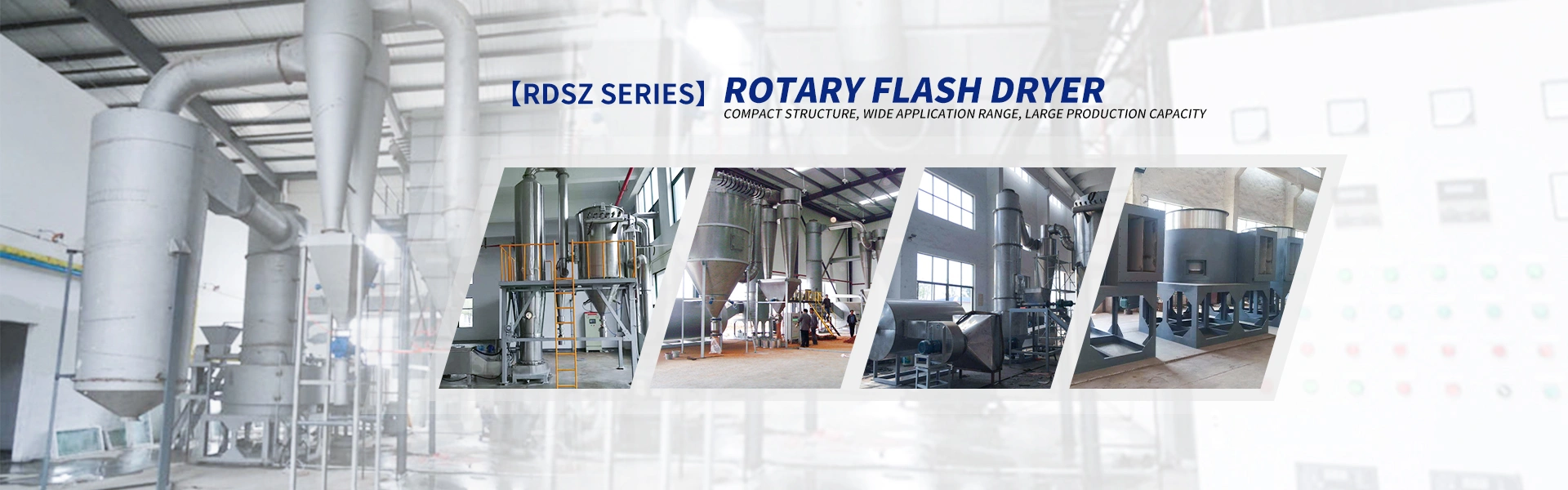

The XSG series of rotary flash dryers are technologically advanced, compact in design, easy to operate, and convenient for maintenance. They enhance the heat transfer between gas and solid, significantly reducing drying time and greatly improving both product yield and quality, with very noticeable energy-saving effects.

view more

Airflow drying is a batch-type, high-heat-efficiency rapid continuous instantaneous drying equipment. Wet materials enter the dryer together with the conveying device and heated air. The two are fully mixed, and due to the large heat and mass transfer area, the purpose of evaporation drying can be achieved in a very short time. The dried finished product is discharged from the cyclone separator, and a small part of the material is recovered and reused from the cyclone separator or bag dust collector. Over the years, through continuous improvement and upgrading, it has developed into four series: Q series (basic type), QG series pulse airflow type, FG series exhaust gas circulation type, and JG series intensified crushing type.

view more

Boiling drying, also known as fluidized bed drying, mainly consists of an air filter, heater, boiling bed main unit, cyclone separator, bag dust collector, high-pressure centrifugal fan, and control panel. Depending on the nature of the raw materials, dust removal equipment can be配套 used. Cyclone separators and bag dust collectors can be selected for dust removal, or one of them can be used alone.

view more

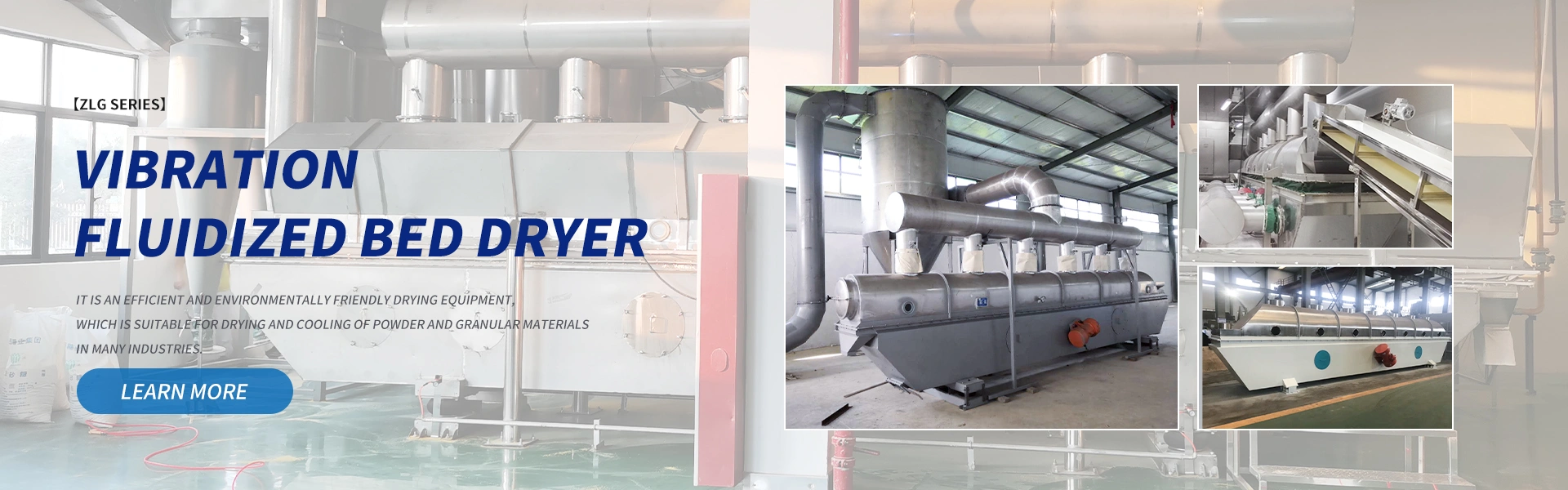

The vibrating fluidized bed dryer generates excitation force through the vibration source, making the material easier to fluidize. The material enters the dryer, and under the action of vibration force and hot air, the material is thrown up and jumps forward along the surface of the fluidized bed. The hot air passes through the fluidized bed to fully exchange heat with the moist material. Then it is dusted by a cyclone separator or bag dust collector and then discharged by an exhaust fan. The dried material is discharged from the discharge port at the other end of the fluidized bed. This machine is suitable for powder drying in chemical, pharmaceutical, food processing, grain, mineral and other industries.

view more

A paddle dryer is a low-speed mixing drying equipment. It is equipped with mixing paddles inside, and wet materials are fully contacted with the heating surface of the heat carrier under the stirring of the paddles, thereby achieving the drying purpose. Its structural form is generally horizontal, adopting a dual-shaft structure. Paddle dryers can be divided into hot air type and conductive type. The hot air type is a drying process in which the material is directly contacted with the heat carrier (such as hot air).

view more

A rotary drum scraper dryer is a continuous drying device with internal heating conduction. The rotating drum adheres to a liquid film through a trough at its lower part. Heat is transmitted via pipes to the inner wall of the drum, then conducted to the outer wall, and subsequently transferred to the liquid film on the outer wall. This causes the moisture in the film to evaporate and dehydrate, thereby achieving the purpose of drying the material. After drying, the material is scraped off the surface of the drum by a scraper and discharged from the machine.

view more

The PLG series plate dryer is a continuous drying equipment mainly based on heat conduction, which is improved and developed from intermittent stirring conduction drying. It consists of multiple layers of fixed hollow heating circular material-carrying discs, a rotating shaft, stirring paddles, and an externally vertically fixed cylindrical body. The heat carrier is introduced into the hollow discs, indirectly heating the wet material on the surface of the discs through heat conduction. The rotating paddles continuously flip and scrape the material to achieve the purpose of rapid drying.

view more

The centrifugal spray dryer is named for its use of a centrifugal atomizer and is one of the widely used drying equipment in industrial production. The working principle of this machine is to add liquid to a high-speed rotating dispersing disc, where the liquid is flung into droplets under the action of centrifugal force, and then dried inside the dryer. On the surface of the dispersing disc, the liquid spreads into a thin film and is ejected at high speed from the edge. The atomization effect depends on the atomizing disc...

view more

The high-speed centrifugal spray drying unit for Chinese herbal medicine extracts is an application of centrifugal spray drying technology in the drying of specific materials. It uses a high-speed centrifugal atomizer to disperse the material into a mist, which then fully contacts hot air to complete instant drying, forming a powder product. The dedicated spray dryer for Chinese herbal medicine extracts is a spray dryer specifically designed to solve the spray drying problems of Chinese herbal medicine extracts and plant extracts.

view more

The YPG series pressure-type spray (cooling) dryer uses a pressure atomizer to atomize solution or paste-like materials into fine droplets by means of the pressure from a diaphragm pump. This significantly increases the surface area, allowing for full heat exchange with hot air to achieve rapid drying (drying time ranges from several seconds to几十 seconds). Ultimately, powder or fine granular products are obtained.

view more

ZPG vacuum harrow dryer is a new type of horizontal batch vacuum drying equipment. Wet materials absorb heat through conduction and evaporate moisture. The scraper agitator continuously removes materials from the heating surface and forms a circulation flow inside the container. After moisture evaporation, it is discharged by the vacuum pump. This machine adopts a large-area jacketed heating method, which has a large heat transfer area and high thermal efficiency. Equipped with a stirring device, it enables the material to form a continuous circulation state inside the cylinder, further improving the heat transfer and mass transfer efficiency of the material.

view more

Cylindrical vacuum dryers heat the material to be dried in a cylindrical chamber and use a vacuum pump to extract air and evaporated water. The drying process takes place under vacuum conditions, significantly accelerating the drying speed of the material. Cylindrical vacuum dryers are suitable for drying materials that require a higher degree of vacuum.

view more

A vacuum drying oven is a device that dries materials by heating them under vacuum conditions. Square vacuum ovens are used for airtight storage of raw materials. Under the action of a vacuum pump, the square chamber is in a vacuum state, which reduces the boiling point of the raw materials' evaporation and significantly accelerates the drying speed of the materials. Vacuum drying equipment can be divided into static drying and dynamic drying. YZG round and FZG rectangular vacuum drying ovens belong to static vacuum dryers, while SZG double-cone vacuum dryers belong to dynamic vacuum dryers.

view more

Freeze drying is to directly transform the moisture or other organic solvents in the material from a solid state into a gas through sublimation, thereby removing the moisture or other solvents in the material. Freeze drying must be frozen at low temperature and carried out in a vacuum state, so it is also called vacuum freeze drying. Sublimation refers to the process in which a solvent changes directly from a solid state (such as water, like dry ice) to a gaseous state without passing through the liquid state. The product obtained by freeze-drying is called lyophilisate. Traditional drying will cause the material to shrink and destroy cells, while the freeze-dried material structure will not be destroyed and can effectively retain the biological and active integrity of the product.

view more

Freeze-drying is different from other drying methods. It directly converts the moisture or other organic solvents in the material from a solid state into a gas through sublimation, thereby achieving the purpose of removing moisture or other solvents. Freeze-drying must be frozen at low temperatures and carried out in a vacuum state, so it is also called vacuum freeze-drying. Sublimation refers to the process in which a solvent changes directly from a solid state (such as water, like dry ice) to a gaseous state without passing through the liquid state. The product obtained by freeze-drying is called lyophilisate.

view more

The DSH series conical spiral belt mixer consists of a conical cylinder, a stirring device, and a transmission mechanism. The stirring device includes a central spiral shaft and a stirring spiral belt that is tightly attached to the inner wall of the cylinder. This machine is suitable for mixing powders and granular materials with high hygiene requirements, as well as for mixing materials with viscous fluids or materials mainly composed of thick, wet, and paste. Widely used in chemical, pesticide, dye, pharmaceutical, feed, fertilizer

view more

The double-cone rotary vacuum dryer is an intermittent sealed drying equipment. During operation, the material is added into a closed container, and a heat source (such as hot water, low-pressure steam or heat transfer oil) is introduced into the jacket of the container. Heat is conducted through the tank wall to heat the raw material. Since the container is under vacuum conditions, the reduced operating pressure causes the moisture (solvent) on the surface of the material to reach boiling point and evaporate rapidly. The wet steam is then sucked away by a vacuum pump and recovered.

view more

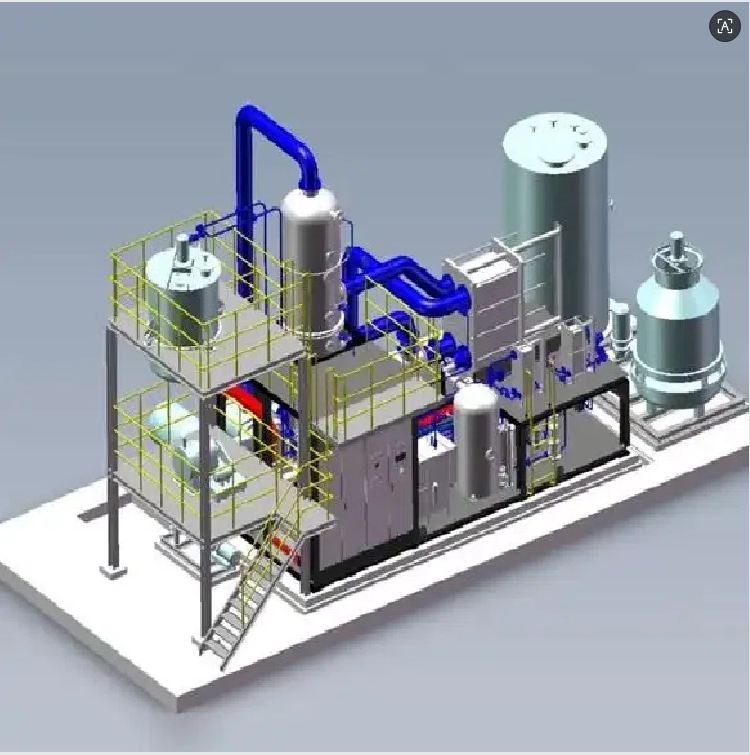

Double-effect evaporator, also known as second-effect evaporator, usually uses the secondary steam generated by the first evaporator as a heating source again and introduces it into another evaporator. As long as the pressure and boiling point of the solution in the evaporator are controlled to appropriately reduce them, the secondary steam generated by the first evaporator can be used for heating. The secondary steam condensation point of the first evaporator is the heating point of the second evaporator. This is the principle of double-effect evaporation. Generally speaking: single-effect evaporation consumes 1.1~1.2 tons of steam per ton of water, and double-effect evaporation consumes 0.6~0.7 tons of steam per ton of water.

view more

MVR evaporator is a new type of equipment that has attracted much attention in the field of evaporation and concentration in recent years and has demonstrated significant industry advantages. It consumes electrical energy or other forms of mechanical energy as the main energy source. Compared with traditional evaporators, it greatly reduces the consumption of raw steam, greatly reduces operating costs, and effectively saves the company's production costs. At the same time, the equipment is compactly arranged, occupies a small area, and consumes less circulating water, which greatly saves land and water resources. In addition, the system can achieve low-temperature operation, is suitable for evaporation and concentration of heat-sensitive materials, retains material quality to a large extent, and is widely used for specific materials in pharmaceuticals and food processing.

view more

The horizontal screw belt mixer consists of a U-shaped cylinder, a stirring screw belt, and transmission components. Stirring screw belts are generally made into double layers. During operation, the outer layer of screw belts collects materials from both sides to the center, while the inner layer of screw belts pushes materials from the center to both sides, forming convective mixing. Spiral belt mixer is generally used for mixing viscous or cohesive granular materials, as well as mixing liquid or paste materials added to the granules.

view more

The WZ series gravity free mixer is composed of a horizontal cylinder, a double blade mixing shaft, and a transmission mechanism. It has strong mixing force and can achieve rapid mixing in a short period of time. It is particularly skilled in handling the mixing of materials with significant differences in physical properties such as density, fineness, and flowability. It is mainly used in fields such as electronic batteries, building mortar, environmental protection, mining, and agriculture, and is suitable for powders, particles, fibers, and other materials

view more

The LDH series plow blade mixer is a single axis forced mixing batch mixing equipment that can handle the mixing of solid powder and granular materials, and is suitable for liquid addition processes. The material is quickly crushed, cut, and dispersed under the strong shear force of the mixing plow blade and auxiliary flying blade, with excellent mixing effect.

view more

DSH Double Spiral Cone Mixer is a new type of high-efficiency mixing equipment improved from the Single Spiral Cantilever Cone Mixer. The machine can be controlled by one (or two) sets of motors and reducers for self rotation and revolution, and adopts asymmetric mixing with two screws. The material mixing range is large and the mixing speed is fast. This machine is suitable for mixing materials such as powders and powders, as well as adding liquids to powders. It has strong adaptability to mixtures and does not mix heat sensitive materials.

view more

The SZH series double cone mixer transfers powder or granular materials into a double cone container through vacuum conveying or manual feeding. As the capacity continues to rotate, the materials undergo complex impact movements in the container to achieve uniform mixing. This machine is energy-saving, easy to operate, has low labor intensity, and high work efficiency. This machine is suitable for mixing powdered and granular materials in industries such as pharmaceuticals, chemicals, food, and building materials.

view more

The SYH series 3D motion mixer, due to the multi-directional movement of the mixing barrel, has multiple cross mixing points for the materials inside the barrel, resulting in high mixing efficiency. The uniformity can reach over 99.9%, and the maximum loading coefficient can reach 0.9 (ordinary mixers have a coefficient of 0.4-0.6). The mixing time is short and the efficiency is high. The mixing barrel of this machine has a unique design, with the inner wall of the barrel finely polished, no dead corners, no pollution of materials, easy discharge, and cleaning

view more

The GHL series high-speed mixing granulator is made by mixing powder materials and binders in a cylindrical container from the bottom into a wet soft material, which is then cut into uniform wet particles by a side mounted high-speed crushing blade.

view more

The working principle of the GFG series high-efficiency boiling dryer is as follows: After the air is purified and heated, it is drawn into the bottom of the hopper by an induced draft fan and passes through the bottom grid plate of the hopper. In the working chamber, fluidization is formed through stirring and negative pressure. Moisture evaporates quickly and is discharged, thereby enabling rapid drying of the material.

view more

Inert particle fluidized bed drying can replace spray drying in many occasions, and is suitable for drying solution materials. Compared with spray drying, it has higher drying intensity and can be dried with lower heat source temperature (such as low-pressure steam, waste hot water, etc.); Under the same conditions, the equipment scale is much smaller (its volume is generally only about 10% of that of the spray drying tower), the system floor area and height are significantly reduced, and the equipment investment is relatively low...

view more

The ZLB rotary granulator is mainly used in industries such as pharmaceuticals, food, granules, chemicals, and solid beverages to make the required particles from stirred materials, especially suitable for materials with high viscosity. All parts of this machine that come into contact with materials are made of stainless steel, with a beautiful appearance, reasonable structure, high granulation forming rate, beautiful particles, automatic discharge, avoiding particle damage caused by manual discharge, and suitable for assembly line operation.

view more

The 30B series universal and efficient crushing unit consists of a crusher, an ESC material collection box, and an ESC vacuum cleaner. Resolve the issue of dust flying during the crushing process of materials. The working principle of this machine is that the material enters the crushing chamber and is crushed by the impact, shear, friction, and mutual impact of the teeth between the high-speed rotating movable and fixed toothed discs. After being screened by a sieve, it becomes the required powder.

view more

Stainless steel mixing tanks are commonly used in the pharmaceutical and food industries. The tank body often features a jacket for heating and cooling. The conical head is formed by spin-forming, and the inner surface is electrolytic mirror polished. It complies with GMP standards. The mixing system uses sanitary-grade mechanical seals. The container insulation employs polyurethane or pearl cotton, and the interfaces use internationally standardized quick-release clamp connections for convenience and hygiene.

view more