Equipment Overview

The rotating flash dryer is a new type of drying equipment that integrates the technologies of air flow drying and material fluidization. It overcomes the drawbacks of high energy consumption in air flow drying and uneven drying in fluidized bed drying, featuring rapid, efficient, and energy-saving characteristics. Compared with other dryers, it makes up for the shortcomings of low efficiency and small output of paddle-conductive dryers, and simplifies the complex process of needing dilution before drying in spray dryers. The rotating flash dryer has advanced technology, compact structure, simple operation, and convenient maintenance. It enhances heat transfer between gas and solid, significantly shortens drying time, greatly improves output and quality, and has very obvious energy-saving effects. It is especially suitable for direct drying of pasty materials and filter cakes.

Working Principle

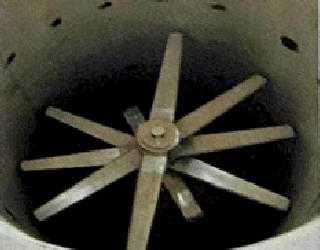

The hot air required for drying enters tangentially into the bottom of the dryer and enters the dryer through a lower annular narrow gap. Under the drive of the agitator, the hot air forms a strong rotating gas flow field. The paste-like material is fed into the dryer through a screw feeder. Under the strong action of the high-speed rotating agitator blades, the material is dispersed under the action of impact force, friction force, and shear force. The blocky material is quickly crushed and fully contacts with the hot air, being heated and dried. After dehydration, the dried material rises with the hot air flow. Large particles are intercepted by the classification ring, while small particles are discharged from the center of the classification ring and then recovered by a cyclone separator and a bag dust collector. Materials that do not meet the drying requirements or large blocks are thrown against the wall by centrifugal force, fall back to the bottom, and are crushed and dried again.

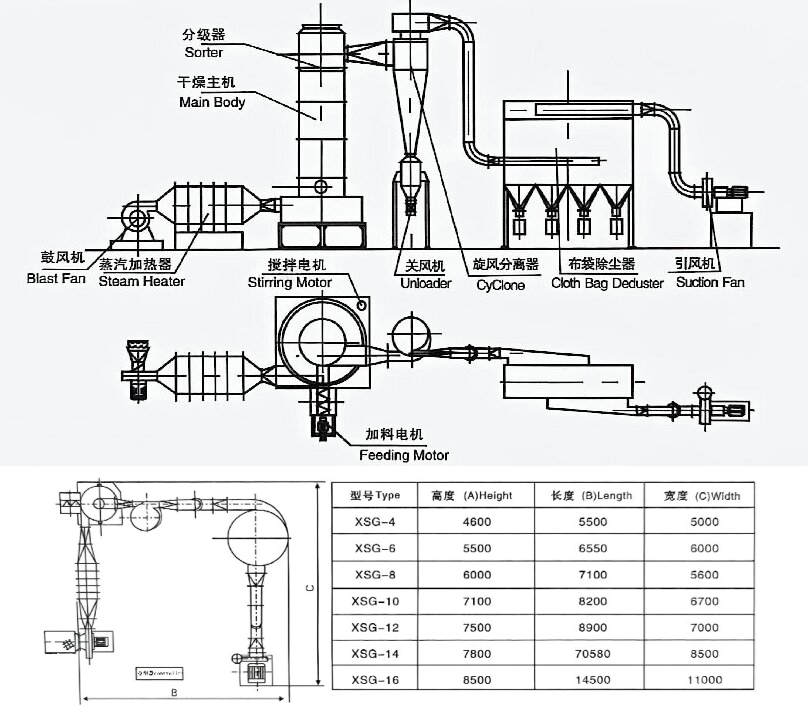

Process Flow Diagram

Structural characteristics

1. An organic combination of technologies such as mixing, crushing, fluidization, and classification.

2. The equipment has a compact structure, small volume, high efficiency, and can operate continuously to achieve 'small equipment, large production capacity.

3. High drying intensity, low energy consumption, and high thermal efficiency.

4. Short material residence time, good product quality, and suitable for drying heat-sensitive materials.

5. Operates under negative pressure or slight negative pressure, with good sealing, high efficiency, and elimination of environmental pollution.

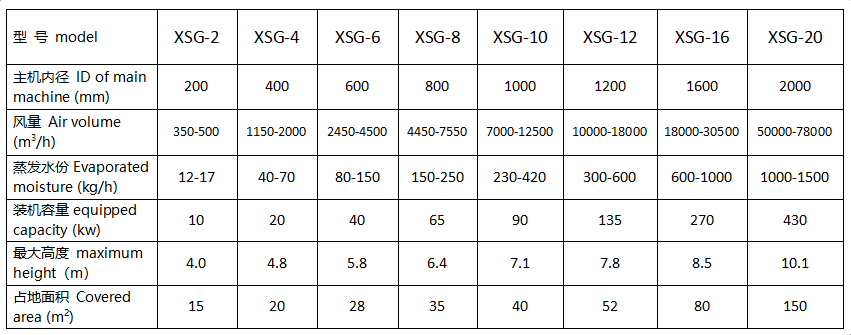

Technical specifications

Note: 1. Water evaporation is the amount of water evaporated per hour when the inlet air temperature is 180°C and the outlet air temperature is 80°C;

2. In addition to the above models, our company can make special designs for users for specific materials;

3. The above installed capacity is a standard match. According to different material characteristics and process requirements, the power match must be adjusted accordingly.

Applicable materials

1. Organic compounds: atrazine (pesticide insecticide), lauric acid, benzoic acid, benzoic acid, fungicide, sodium oxalate, cellulose acetate, organic pigments, etc.

2. Dyes: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various azo dye intermediates.

3. Inorganic substances: borax, calcium carbonate, hydroxides, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydroxides, various heavy metal salts, synthetic cryolite, etc.

4. Food: soy protein, gelatinous starch, wine trough, wheat sugar, wheat starch, etc.

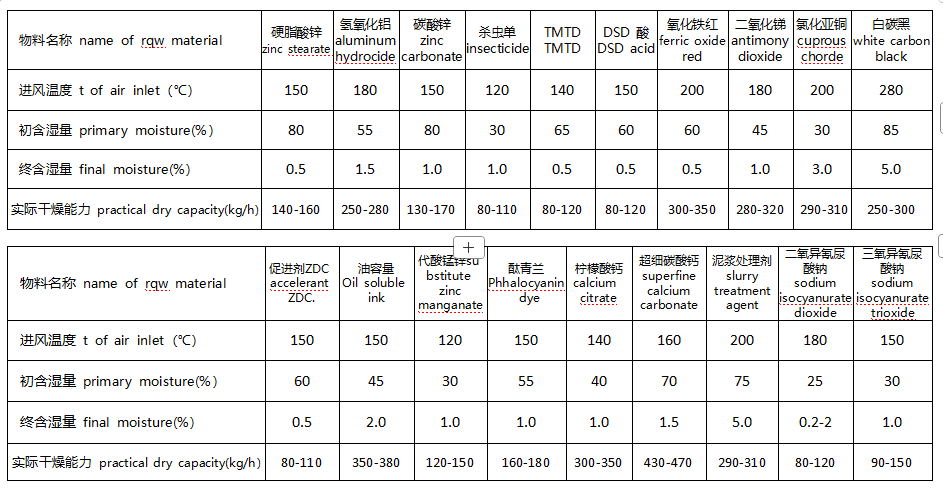

Application examples (based on type 6 flash evaporation)

Hot Tags: Spin flash dryer Air flash dryer Flash dryer