Air flow dryer overview

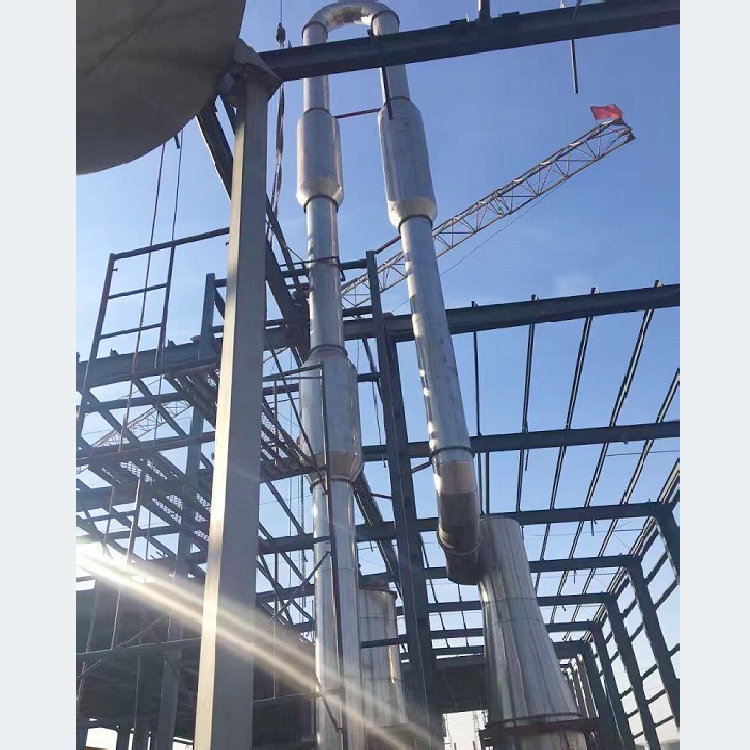

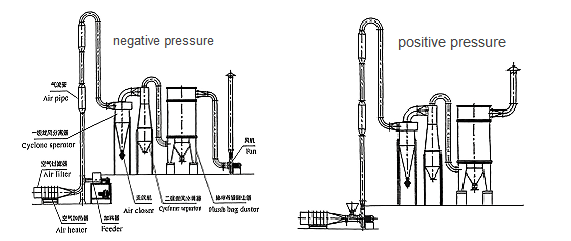

Air flow drying is a fast, efficient, continuous and instantaneous drying equipment. The wet material is transported through the feeding device and is carried into the dryer by the heated high-speed air. The two are fully mixed. Due to the large heat and mass transfer area, evaporation drying can be achieved in a very short time. The dried finished product is discharged through the cyclone separator, and a small amount of material is recycled from the cyclone separator or bag dust collector. Over the years, after continuous improvement and upgrading, the air flow dryer has developed into four series: Q series (basic type), QG series pulse air flow type, FG series tail gas circulation type and JG series enhanced crushing type. The following are introduced respectively:

1. QG series pulse air dryer

The QG series pulse air dryer uses the periodic changes in the drying pipe diameter to cause the hot air speed in the pipe to change accordingly, forming pulses. Due to the large speed difference between the material and the hot air, a high heat and mass transfer rate is always maintained, which strengthens the entire drying process. After air flow drying, the non-bound moisture in the material can be almost completely removed (for example, for materials such as starch with a moisture content of ≤40% when feeding, the moisture content can be reduced to 13.5% when discharging). Compared with ordinary dryers, its production capacity is significantly improved, thus bringing higher economic benefits.

Product features

The QG airflow dryer has a high degree of automation, low investment, low energy consumption, and a small footprint. It is a drying equipment with a wide range of applications and high cost performance.

Applicable raw materials

This machine is suitable for pharmaceutical, chemical, food, building materials, plastics and other industries. It can be used to dry and dehumidify powdery and fine particle materials, such as starch, fish meal, salt, distiller's grains, feed, gluten, plastic resin, mineral powder, coal powder, chloric acid, 2,3-dihydrochloric acid, polyvinyl chloride, sodium sulfate, sodium bisulfite, etc.

Our company provides technical consultation on air flow dryers and can design non-standard air flow dryers for customers.

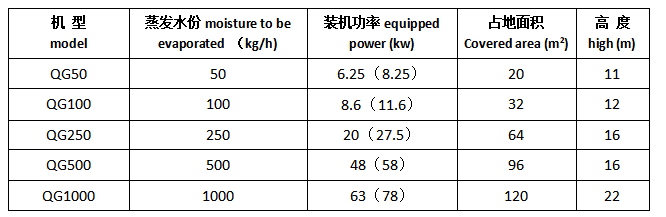

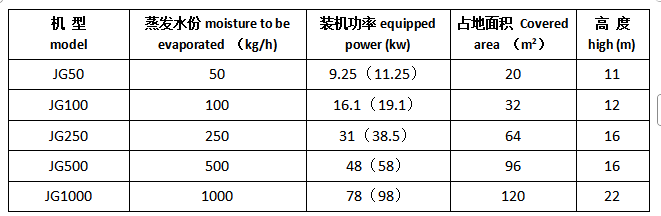

Technical specifications

Note: The figures in parentheses are the installed power when equipped with bag dust collector.

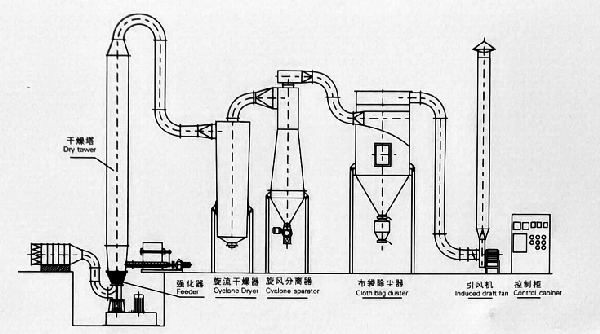

2. JG series airflow dryer

Working principle

The JG series airflow dryer can quickly remove moisture (mainly surface moisture) from easily dehydrated granular and powdery materials.In air flow drying, due to the short residence time of the material in the dryer, the quality of the dried product is best controlled. Our factory's enhanced airflow drying is based on the basic type and consists of a set of infinitely adjustable speed intensifiers. The wet material first enters the intensifier through the spiral feeder. In the intensifier, the wet material is crushed into fine particles under the rapid rotation and push of the pulverizing knife, and then fully mixed with the hot air flow, which greatly increases the heat transfer and mass transfer area. It is dried in the drying tube while moving toward the discharge port for further uniform drying. The wet weight particles that cannot be attracted by the wind continue to be crushed and dried until they can be sucked away by the wind and enter the drying tube.

Main purpose

This machine is particularly suitable for materials with high moisture content, such as white carbon black, copolymers of vinyl acetate and vinyl chloride, acetate fiber floc, catalyst, C.M.C, CT-1 resin, gypsum, electrolytic manganese dioxide, anthraquinone sulfonate ammonium salt, fluorite, diatomaceous earth, silica gel catalyst, bone powder, high soil, potassium perchlorate sulfonamide drugs, synthetic resin, active gluten, active clay, chemical filter cake, rutile diamond powder, sebacic acid, copper sulfate, aluminum sulfate, sodium sulfate, calcium phosphate, phosphorylated starch, dye, calcium citrate, coal slurry, dough shaped bread, rice bran, clay, clay, clay. Cement, urea, bentonite, spherical clay, aluminum hydroxide, barium hydroxide, calcium lactate, food, water washed high soil Cyanuric acid, gypsum slurry, lime, biological products, carbon black, calcium carbonate slurry, sludge residue, organic chemicals aluminum stearate, iron oxide, organic fuel, corn protein feed, wet mud, mica powder, pharmaceuticals, pigments, potassium dichromate pulp, distiller's grains residue, etc.

Technical specifications

Note: The figures in parentheses are the installed power when equipped with bag dust collector.

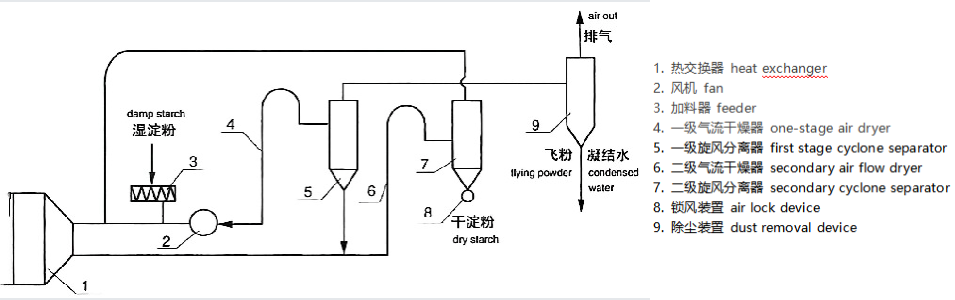

3. FG series airflow dryer

Working principle

The working principle of FG series airflow dryer is to divide the drying of wet materials into two steps. The raw materials are first subjected to a first stage positive pressure drying using a mixture of exhaust gas from the second stage drying and supplementary hot air. The high-temperature and low humidity exhaust gas after use is discharged outside the machine, and the dried semi-finished product is subjected to a second stage negative pressure drying using fresh hot air. Dry finished products are measured and packaged. The used high-temperature and low humidity exhaust gas is used for primary drying, thus completing a good cycle drying process. The amount of supplementary hot air can be adjusted as needed, making the machine widely applicable.

Applicable raw materials

This equipment is widely used for drying powdered and granular materials in industries such as food, chemical, pharmaceutical, and building materials. The products that have been dried using this series include starch, glucose, fish powder, sugar, sugar, wine troughs, feed, gluten, plastic resin, coal powder, dyes, etc.

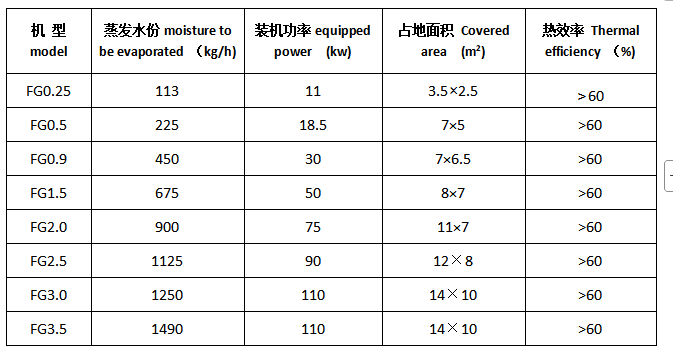

Technical specifications

Hot Tags: QG airflow dryers FG series airflow dryers JG series airflow dryers