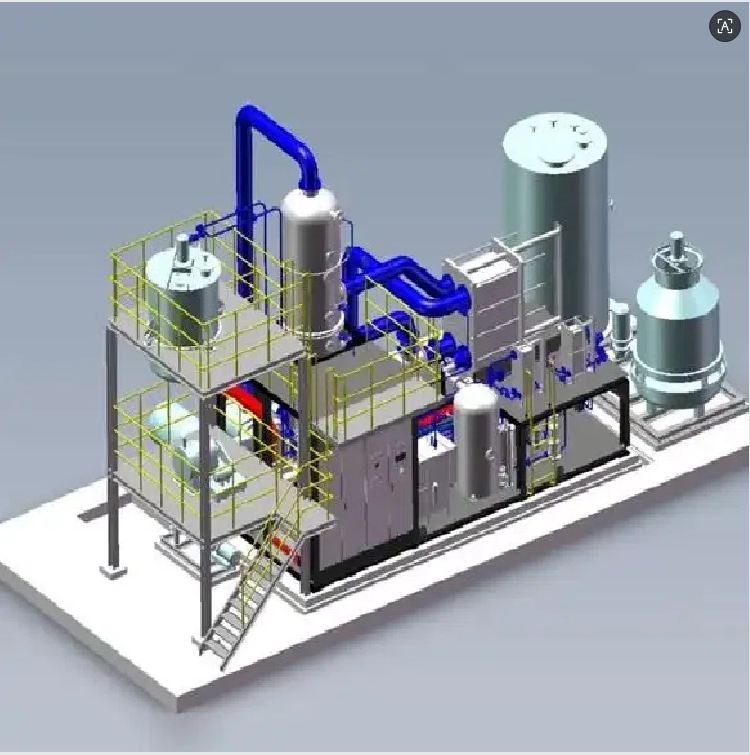

Extraction and concentration system

-

Single effect concentrating evaporatorA single-effect evaporator generally refers to a single independent evaporator. The secondary steam generated when evaporating a solution is no longer used, and is suitable for the evaporation of small-scale solutions. Single-effect evaporators rarely use intermittent evaporation. Common operating modes include semi-intermittent evaporation, continuous batch evaporation, continuous evaporation, etc.read more

-

Double-effect evaporation and concentration systemDouble-effect evaporator, also known as second-effect evaporator, usually uses the secondary steam generated by the first evaporator as a heating source again and introduces it into another evaporator. As long as the pressure and boiling point of the solution in the evaporator are controlled to appropriately reduce them, the secondary steam generated by the first evaporator can be used for heating. The secondary steam condensation point of the first evaporator is the heating point of the second evaporator. This is the principle of double-effect evaporation. Generally speaking: single-effect evaporation consumes 1.1~1.2 tons of steam per ton of water, and double-effect evaporation consumes 0.6~0.7 tons of steam per ton of water.read more

-

MVR evaporation concentration systemMVR evaporator is a new type of equipment that has attracted much attention in the field of evaporation and concentration in recent years and has demonstrated significant industry advantages. It consumes electrical energy or other forms of mechanical energy as the main energy source. Compared with traditional evaporators, it greatly reduces the consumption of raw steam, greatly reduces operating costs, and effectively saves the company's production costs. At the same time, the equipment is compactly arranged, occupies a small area, and consumes less circulating water, which greatly saves land and water resources. In addition, the system can achieve low-temperature operation, is suitable for evaporation and concentration of heat-sensitive materials, retains material quality to a large extent, and is widely used for specific materials in pharmaceuticals and food processing.read more