System overview

MVR evaporator, as a piece of equipment that has attracted much attention in the field of evaporation and concentration in recent years, has demonstrated significant industry advantages. It consumes electrical energy or other forms of mechanical energy as its main energy source. Compared with traditional evaporators, it greatly reduces the consumption of raw steam, significantly reduces operating costs, and effectively saves the company's production costs. At the same time, the equipment is compactly arranged, occupies a small area, and consumes less circulating water, which greatly saves land and water resources. In addition, this system can achieve low-temperature evaporation, which is especially suitable for heat-sensitive materials and can preserve the quality of materials to a great extent. It is widely used in pharmaceutical, food and other industries for specific materials.

The MVR evaporator has a short process, high degree of automation, and easy control, which reduces labor intensity and improves production efficiency.

Working principle

Working principle of the MV evaporation system: This system uses mechanical vapor recompression (MVR) technology. It uses the secondary steam generated in the evaporation system. After being compressed by the compressor, the pressure and temperature of the secondary steam increase, and the heat enthalpy increases. It is then sent to the heating chamber of the evaporation system and used again as heating steam to heat the feed liquid and maintain the boiling state. The heated steam is condensed into water and discharged. In this way, the steam that was originally intended to be discarded is fully utilized, latent heat is recovered, and thermal efficiency is improved. The economy of raw steam is equivalent to multi-effect evaporation, which reduces the need for external heating and cooling sources and reduces energy consumption. Low-temperature and low-pressure steam technology is now used to form a negative pressure in the effect body through a vacuum pump, reducing the boiling point of water, and the product evaporation temperature is lower than 60°C. , more suitable for concentrating heat-sensitive materials and improving product quality.

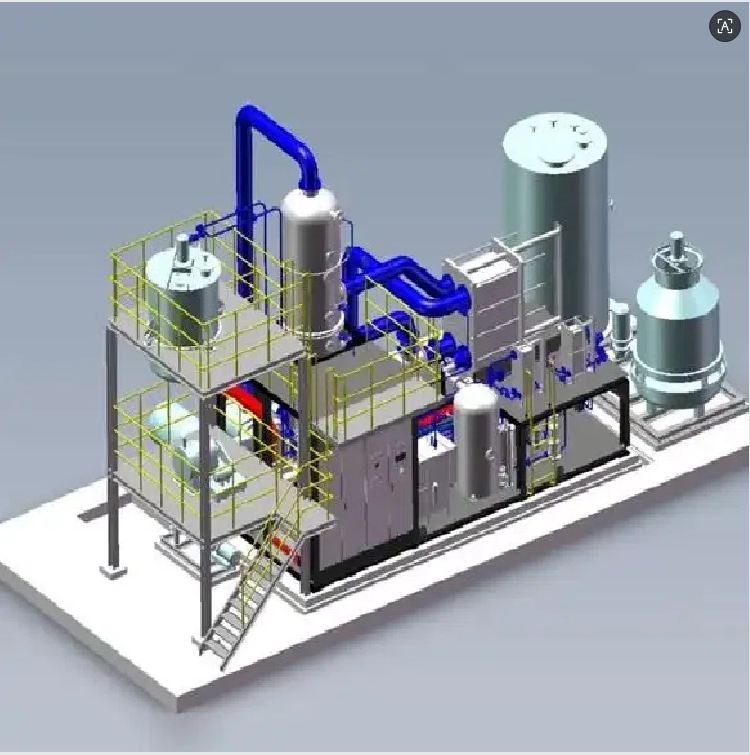

schematic structural diagram

The MVR concentration unit mainly consists of a steam compressor, heater, separator, crystallizer, condenser and some auxiliary equipment.

Scope of application

MVR evaporators are widely used in food processing, juice concentration, beverage production, dairy production, chemical industry, pharmaceutical industry, wastewater treatment, environmental protection engineering and other fields. Application method:

◆ Evaporation concentration; ◆ Evaporation crystallization; ◆ Low temperature evaporation.

Performance and features

1. Adopt the principle of mechanical vapor recompression

◆ Low unit energy consumption;

◆ The temperature difference is small and the product evaporates gently;

◆ Usually used for single-effect concentration with short product residence time;

◆ This process is simple and practical.

2. Technical features

◆ The energy saving effect is obvious and the energy consumption is low;

◆ Small footprint and few supporting public works projects;

◆ Since the heater is also a condenser of secondary steam, there is no need to configure a separate condenser and no need to circulate cooling water;

◆ Stable and reliable operation, highly automated;

◆ No need to generate steam, only appropriate electric energy can maintain normal evaporation;

◆ Since single-effect evaporator is usually used for heating and equipped with a large-flow circulation pump, the product residence time is short;

◆ Low operating costs.

Technical parameters

项目名称 Project name

参 数 parameter

蒸发能力 Evaporation capacity (t/h)

0.5-5

蒸发温度 Evaporation temperature (℃)

≤100

蒸发每吨水耗电量 Electricity consumption per ton of water evaporated (kw)

50-80

蒸汽消耗量 Steam consumption (t/h)

0-0.1

进料含固量 Feed solid content

无 None

出料含固量 Discharge solid content

可以直接蒸发到结晶 Can be directly evaporated to crystallization

蒸发模式 Evaporation mode

降膜、升膜、强制循环等方式 Falling film, rising film, forced circulation, etc.

换热部件 Heat exchange parts

列管式换热器 Tube and tube heat exchanger

Hot Tags: MVR Concentrate Evaporation, MVR evaporator MVR Concentrate Evaporation