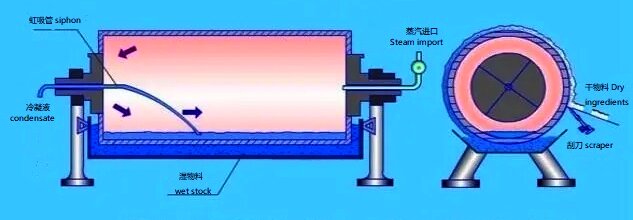

Working principle

A drum scraper dryer is an internally heated conductive continuous drying equipment. The rotating drum forms a material film with the liquid material through a trough at its lower part. Heat is transmitted through pipes to the inner wall of the drum, then conducted to the outer wall, and further transferred to the liquid film. Water in the film evaporates and is dehydrated, thus drying the material. After drying, the material is scraped off the drum by scrapers installed on the outer surface of the drum and enters a screw conveyor below the scrapers. The dry material is discharged along with the screw conveyor and then packaged.

Performance characteristics

1. High thermal efficiency. The heat transfer mechanism of the drum dryer belongs to conductive heat transfer, and the direction of heat transfer is consistent with the direction of mass transfer. Except for the heat loss from the cylinder surface and radiation, all other heat is used for the evaporation of the wet film of the material on the drum, and the thermal efficiency can reach 70%-80%.

2. The operation is flexible and has a wide range of applicability. Factors such as feed concentration, coating film thickness, heating medium temperature, and drum speed all affect the drying efficiency of the drum dryer. These factors are independent of each other and not interrelated. Through reasonable adjustment and control, this brings great convenience to the operation of the drum dryer, enabling it to adapt to the drying of various materials and meet different production requirements.

3. The operation is flexible and has a wide range of applicability. Factors such as feed concentration, coating film thickness, heating medium temperature, and drum speed all affect the drying efficiency of the drum dryer. These factors are independent of each other and not interrelated. Through reasonable adjustment and control, this brings great convenience to the operation of the drum dryer, enabling it to adapt to the drying of various materials and meet different production requirements.

4. The drying rate is high. Since the paint film applied on the cylinder wall is relatively thin, generally between 0.3-1.5mm, and the heat transfer and mass transfer directions are consistent, the evaporation intensity on the film surface can be maintained at 20-70 kg H2O/m². High drying rate. Due to the thin film of the coating applied to the cylinder wall, generally between 0.3-1.5mm, and the consistent direction of heat and mass transfer, the surface of the film can maintain 20-70kg The evaporation strength of H2O/m2. h.

Installation requirementsThe installation of this machine is based on the overall layout, with a flat ground. A pressure gauge and safety valve should be installed at the inlet of the steam pipe, and all steam inlet flanges should be securely connected.

Adapt to materials

Suitable for drying liquids or viscous materials in industries such as chemical, dye, pharmaceutical, food, metallurgy, etc.

Routine maintenance1. Regularly check the flexibility of rotating parts and whether there is any jamming phenomenon. Chain wheels and other components should be lubricated regularly, and measuring devices such as pressure gauges should be calibrated regularly for errors. If there is severe wear on the triangular belt transmission components, they should be replaced in a timely manner.

2. For maintenance of electric motors and reducers, please refer to the instructions for use and maintenance of electric motors and reducers.

Installation and debugging

1. After the installation of this machine, a trial operation experiment should be conducted first

2. Jogging the main motor to observe the correct rotation of the main drum.

3. Observe whether the main drum and various transmission components rotate flexibly, whether the steam inlet and outlet are connected, and whether the pressure gauge is within the working pressure range.

4. Start the motor, and the main drum runs smoothly. When the temperature rises, add materials, and then adjust the motor speed and the uniformity of the material film on the drum to control the final water content of the material.5. Start the winch motor, output dried finished materials, and adjust the speed of the winch motor according to the amount of dried finished products.

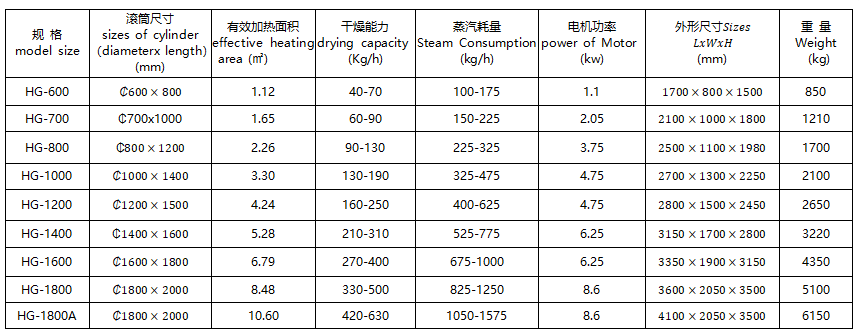

Technical specifications

Note: If required by the customer, we can design and manufacture an upper feeding double drum dryer for them.

Hot Tags: HG series rotary drum scraper dryer rotary drum scraper dryer drum scraper dryer