Equipment Overview

This dryer uses high-pressure drying air to atomize the material, with droplets sprayed onto the surface of a boiling medium (inert particles). The droplets undergo dual heat transfer from both hot air and the medium, creating lower internal pressure that allows water molecules to rapidly diffuse and escape, completing the drying process in seconds (the exact time depends on the material properties). The intense movement of the boiling medium strips and breaks up the surface material film, which is then discharged with the hot air and collected by a collection system. The medium particles rise to the top of the spray tower, where they freely settle due to reduced air velocity, then get covered by new material droplets to start a new drying cycle. The entire drying process operates continuously, with short drying times and minimal changes to the material's properties, meeting quality requirements. This machine solves problems typically encountered in spray drying of highly viscous materials, such as poor atomization and wall adhesion.

◆ Inert particles in a fluidized bed can disperse and grind materials, enabling the dispersion and fluidization of non-fluidizable paste-like or solution-like materials. This enhances heat and mass transfer effects, accelerates material drying speed, improves thermal efficiency, and allows for the direct production of granular materials without the need for screening or crushing. Commonly used fluidizing media are inert particles with diameters of 1~5mm, such as glass beads, ceramic balls, and steel balls.

◆ The inert particle fluidized bed dryer can replace spray dryers in many applications and is suitable for drying solution materials. Compared with spray drying, it has higher drying intensity and uses a heat source at a lower temperature (such as low-pressure steam, waste hot water, etc.). Under the same conditions, the equipment scale is much smaller (its volume is usually about 10% of that of a spray dryer tower), the system's floor space and usage height are significantly reduced, the equipment investment is correspondingly lowered, and the system energy consumption is also significantly reduced.

Product features

◆ High degree of fluidization, uniform heating of materials, and sufficient heat exchange;

◆ Compact structure, small footprint, high evaporation intensity per unit volume;

◆ Continuous operation, able to adapt to large-scale production;

◆ Wide adaptability, can be widely applied in industries such as traditional Chinese and Western medicine, chemical industry, food additives, etc., meeting GMP requirements;

◆ When the solvent is an organic solvent, an inert gas closed-loop circulation method can be used to achieve solvent recovery while the material is dry.

◆ Based on the melting point, viscosity and other properties of the material, suitable control temperature, medium particle size and material can be selected. For example, hollow particles can be used as the drying medium. According to the material properties, pulse bag dust collector or wet spray dust collector can be selected as the secondary dust removal equipment. Based on the user's conditions and the temperature that the material can withstand, steam, electricity or hot air furnace can be selected as the heat source.

Working principle

◆ Spray drying technology is a process that atomizes liquid raw materials into tiny droplets, which then come into full contact with a hot medium to be rapidly dried into powder products. Its core components include: atomization process, heat exchange, drying stage, product collection, and exhaust gas treatment.

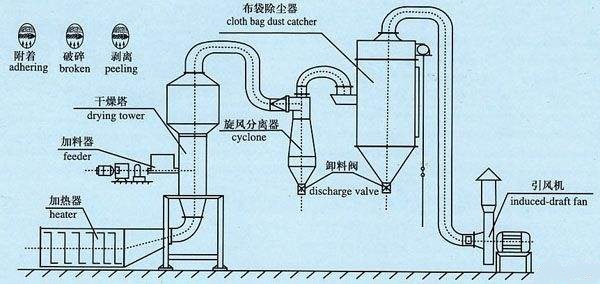

◆ The atomization process is the basis of spray drying, which often disperses liquid materials into fine droplets through nozzles. The raw liquid is pumped into the spray tower by a feeding pump, atomized by compressed air, and forms a thin coating on the surface of inert particles in a boiling state. The atomization effect is influenced by factors such as material concentration, viscosity, nozzle structure, and pressure. Droplet size is related to factors such as slurry moisture content, viscosity, flow rate, and nozzle inlet air pressure. Optimal operating parameters should be selected to obtain ideal droplets.

◆ Heat exchange is the core of drying. During the drying process, the material receives heat simultaneously from hot air and an inert medium, enabling rapid heat transfer which causes water evaporation and thus achieves drying. This highly efficient heat transfer method allows the drying process to be completed in an extremely short time, usually only a few seconds.

◆ The drying process can be divided into four stages: acceleration drying stage, constant-rate drying stage, deceleration drying stage, and equilibrium stage. In the acceleration stage, the surface temperature of the droplets slightly increases, and water evaporates rapidly. In the constant-rate stage, the material surface is always moistened by water, and the evaporated water is free water. In the deceleration stage, the vapor pressure on the material surface is lower than the saturated vapor pressure, leading to a decrease in drying rate and a gradual increase in surface temperature.

◆ Product collection and waste gas treatment are essential to ensure product quality and meet environmental protection requirements. In inert particle spray drying, the dried material is crushed into powder due to intense medium movement collisions, then discharged with hot air and collected via a cyclone separator. The waste gas is subsequently filtered through a bag filter before being released.

Process flow

Application scope

◆ From an industry application perspective, inert particle spray drying technology can be widely used in biopesticides, medicine, food microorganisms and other fields. It has the advantages of fast drying speed, suitable for heat-sensitive materials, wide application range, and good product fluidity. For example, the spray drying device can handle solutions with a solid content of less than 60%. There is no need for further crushing or screening after drying, simplifying the production process.

◆ Closed-loop spray dryers are suitable for suspensions prepared with organic solvents, using inert gas as the drying medium to achieve oxidation-free product drying and medium recovery. They are commonly used for drying precision ceramics and pharmaceutical products.

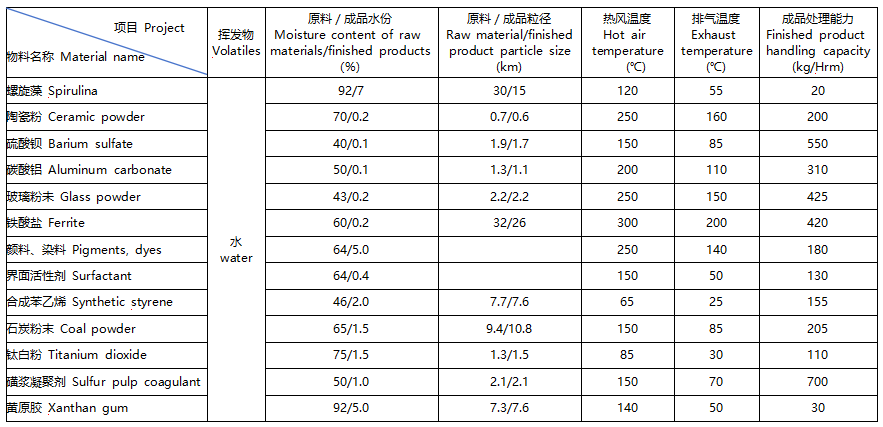

◆ This process is suitable for drying various solutions, suspensions, emulsions, paste materials, thin paste materials, filter cake materials, such as dyes, pigments, coatings, agricultural chemicals, biochemical products, soybean milk (flour making), humic acid, Chinese herbal extracts, pesticides, lignin, pectinase, etc.

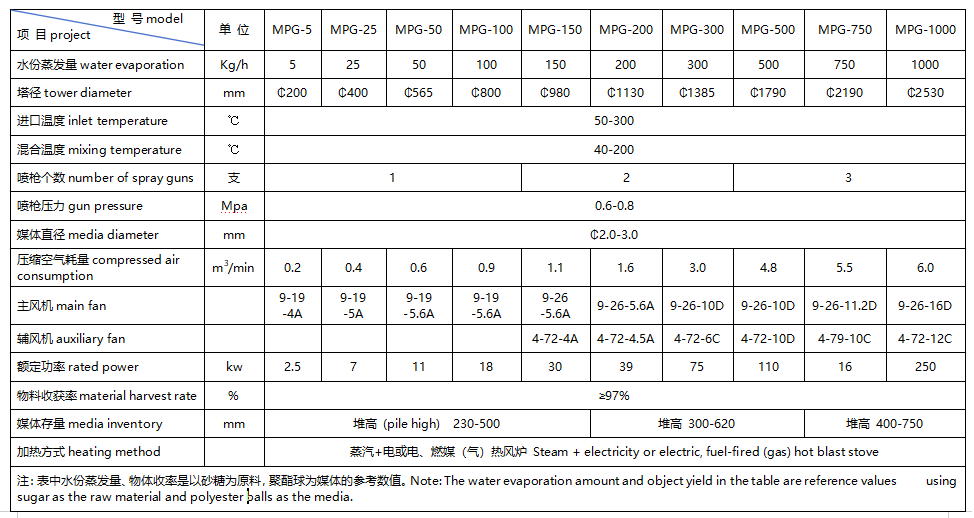

◆ Typical raw materials: iron oxide red, iron oxide yellow, iron oxide black, fermentation powder, diatomaceous earth, titanium dioxide, starch, sulfide iron brown, calcium carbonate, sodium nitrite, humic acid, barium sulfate, aluminum carbonate, scarlet acid, traditional Chinese medicine extract, concrete water reducer, potato slurry.Technical parameters

Application examples

Hot Tags: Inert particle fluidized bed drying machine Inert particle boiling dryer Inert particle fluidized bed dryer