Equipment Overview

Centrifugal spray dryers are named for their use of centrifugal atomizers and are one of the most widely used drying equipment in industrial production. The working principle of this machine is to add liquid to a high-speed rotating dispersing disc, where the liquid is thrown into droplets under the action of centrifugal force, and then dried inside the dryer. On the surface of the dispersing disc, the liquid spreads into a film and is ejected at high speed at the periphery. The atomization effect depends on factors such as the linear velocity at the edge of the atomizer, the feeding rate, and certain physical properties of the raw material.

Working Principle

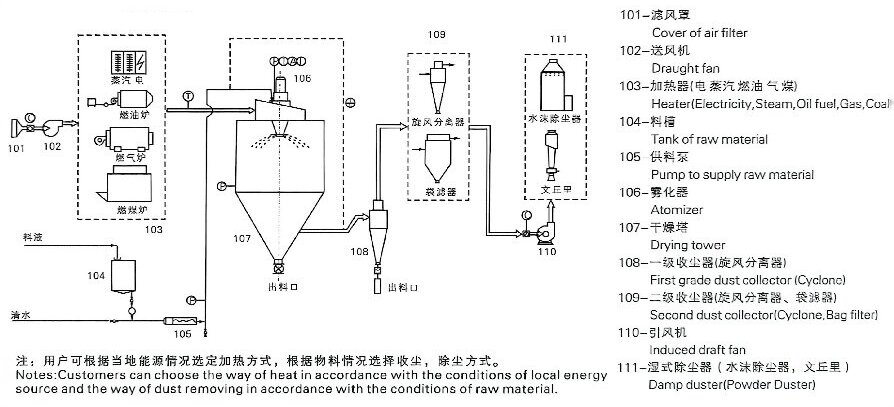

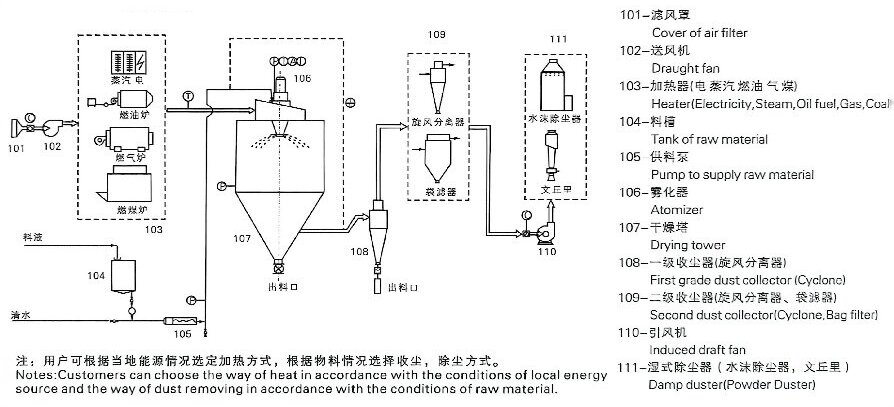

Air that has been filtered and heated enters the air distributor at the top of the dryer, then descends uniformly in a spiral within the drying chamber. Liquid is dispersed into extremely fine droplets by the high-speed rotation of the atomizer at the top of the tower, and subsequently comes into contact with hot air, being dried into finished product in an extremely short time. The finished product is continuously discharged from the bottom of the drying tower or by a cyclone separator, while exhaust gas is expelled by an exhaust fan.

Performance Features

1. Fast drying speed: After atomization, the surface area of the liquid is greatly increased, and 95%-98% of the moisture can be evaporated instantly in the hot air stream, with the drying process taking only a few seconds, making it especially suitable for drying heat-sensitive materials.

2. The product has good uniformity, flowability, and solubility, with high purity and quality.

3. The production process is simplified, and operation control is convenient. Liquids with moisture content of 40-60% (up to 90% for special materials) can be dried into powder or granular products in one step, eliminating the need for crushing and screening after drying, reducing production processes, and improving product purity. The particle size, bulk density, and moisture content of the product can be adjusted within a certain range by changing operating conditions, making control and management very convenient.

Applicable raw materials

1. Chemical Industry: Sodium fluoride (potassium), alkaline dye pigments, dye intermediates, compound fertilizers, formaldehyde silicate, catalysts, sulfuric acid agents, amino acids, silica, etc.

2. Plastic Resins: AB, ABS emulsion, urea-formaldehyde resin, phenolic resin, melamine (urea) formaldehyde resin, polyethylene, polyvinyl chloride, etc.

3. Food Industry: Whole milk powder, gelatin, cocoa powder, substitute milk powder, blood powder, egg white (yolk), etc.

4. Food and Plants: Oats, chicken broth, coffee, instant tea, seasoned spices, meat proteins, soybeans, peanut proteins, hydrolysates, etc.

5. Sugar Industry: Corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

6. Ceramics: Aluminum oxide, ceramic tile materials, magnesium oxide, talc powder, etc.

Drying system flow diagram

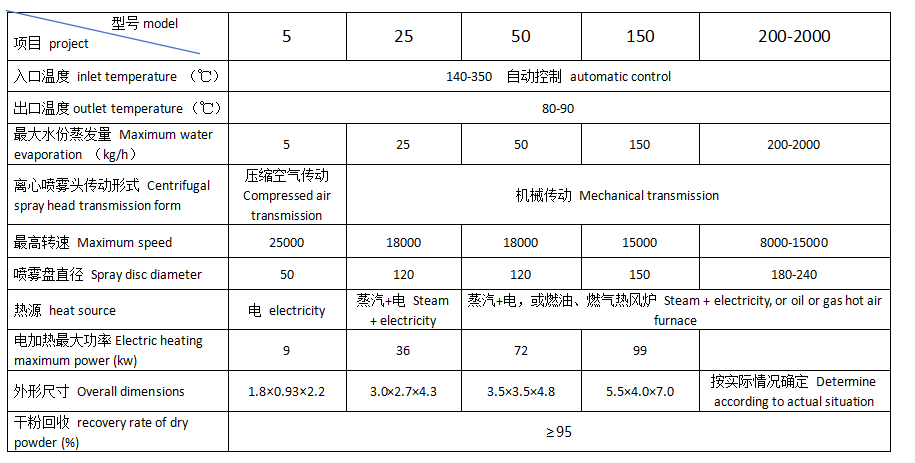

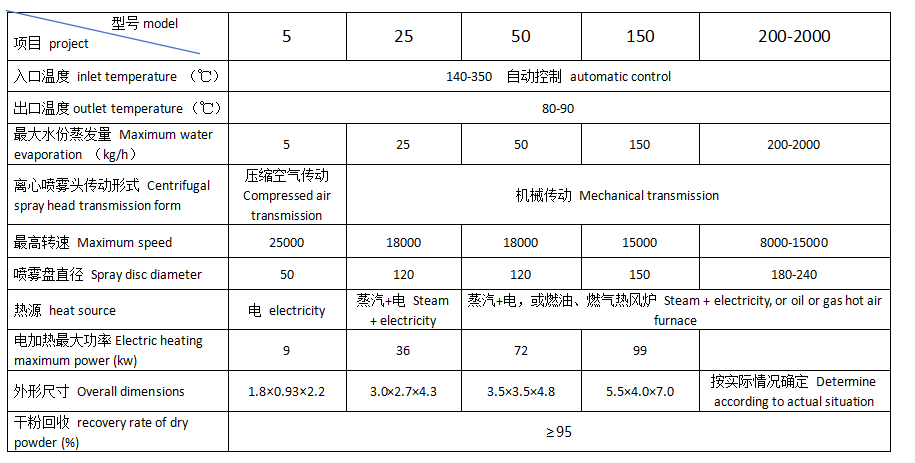

Technical specifications

Note: The amount of moisture evaporation is related to the characteristics of the material and the inlet and outlet air temperatures. When the outlet temperature is 90°C, the moisture evaporation curve is shown in the above figure (for selection reference). As products are continuously updated and parameters change, we regret that we cannot notify in advance.

Ordering Instructions

1. Name and properties of the feed liquid: solid content (or water content), viscosity, surface tension, pH value.

2. The capacity of the dried powder, allowable residual water content, particle size, and allowable maximum temperature.

3. Production capacity, daily operating hours.

4. Available energy sources: steam pressure and availability, electrical capacity, available coal, oil, and gas quantities.

5. Control requirements: whether the inlet and outlet temperatures need automatic control.

6. Powder collection requirements: whether to install a bag filter, and environmental requirements for exhaust gas emissions.

7. Any other special requirements.

Hot Tags:

High-speed centrifugal spray dryer Centrifugal spray dryer Centrifugal spray drying machine