Working principle

After being fed into one end of the dryer, the wet material is evenly distributed and dispersed in the dryer by flipping the plate reader evenly distributed in the inner cylinder, and fully contacts with the hot air flowing in parallel (counter current), accelerating the heat transfer during drying and transmitting it to the driving force. During the drying process, the material can be controlled to move to the star shaped discharge valve in another section of the dryer to discharge the finished product under the action of the inclined plate and hot air flow.

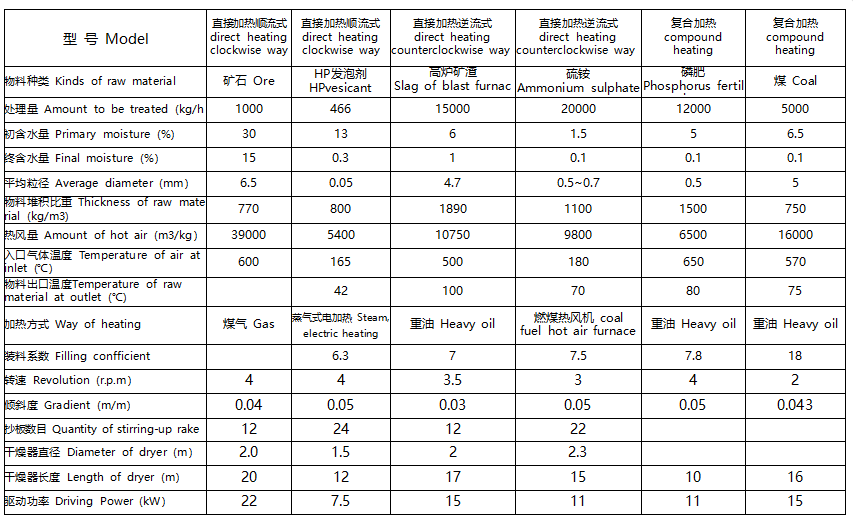

Application areasSuitable for large particles and high-specific-gravity materials that require drying in chemical engineering, mining, metallurgy and other industries, such as ores, blast furnace slag, coal, metal powders, phosphate fertilizers, and ammonium sulfate.

Materials with special drying requirements for powders and granular materials, such as HP foaming agents, distillation residues, light calcium carbonate, active bleaching earth, magnetic powder, graphite, and medicinal dregs.

Materials that require low-temperature drying and continuous large-scale drying.

The rotary drum dryer has a large production capacity.

The heating fluid encounters low resistance and consumes less energy when passing through the cylinder.

It can meet the requirements of different material properties and has strong adaptability.

It operates stably, has low operating costs, and provides good drying uniformity.

Structural schematic diagram

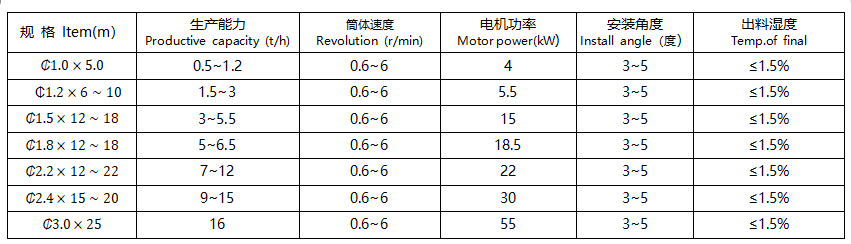

Technical parameters

Application examples

Hot Tags: HZG rotary drum dryer Rotary kiln dryer Rotary drum drying machine