Working principle

The material powder particles are in a fluidized boiling state in the raw material container (fluidized bed). The purified hot air is fully mixed and preheated. At the same time, the binder solution is atomized and sprayed into the mixture through the atomizer, which causes multiple powder particles to aggregate and form particle clusters containing the binder. Due to the continuous drying effect of hot air on the material, the water in the agglomerated particles evaporates and the binder solidifies. This process is repeated until product requirements are met.

Application

1. Pharmaceutical granulation and coating

◆ Granulation: tablet granules, granule granules, capsule granules.◆ Coating: granule, pill protective layer, color preparation, sustained-release, film, enteric coating.

2. Food granulation and coating

◆ Sugar, coffee, cocoa powder, cream, powdered fruit juice, amino acids, seasonings, puffed foods.

3. Pesticide, pigment, dye granulation

4. Drying of powdered, granular, and block materials

Performance characteristics

◆ Improve flowability and reduce dust generation through powder granulation;

◆ Enhance solubility of the powder via granulation

◆ Complete mixing, granulation, and drying in a single device (one-step granulation method);

◆ Use anti-static filter materials to ensure safe equipment operation;

◆ The binder atomizer employs a multi-fluid spray gun, resulting in uniform droplets and significantly improving product pass rate;

◆ The equipment has no dead corners, allowing for convenient, rapid, and clean loading and unloading of materials.

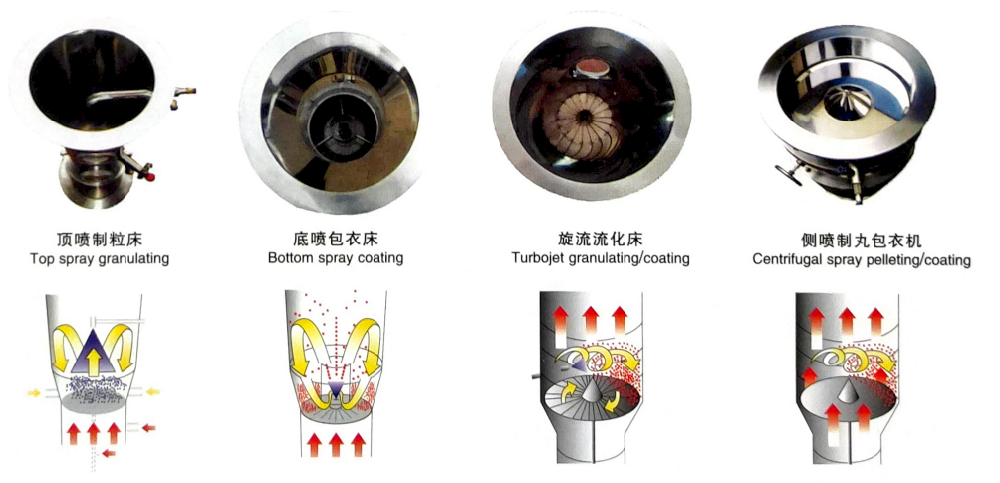

Optional fluidized beds and features

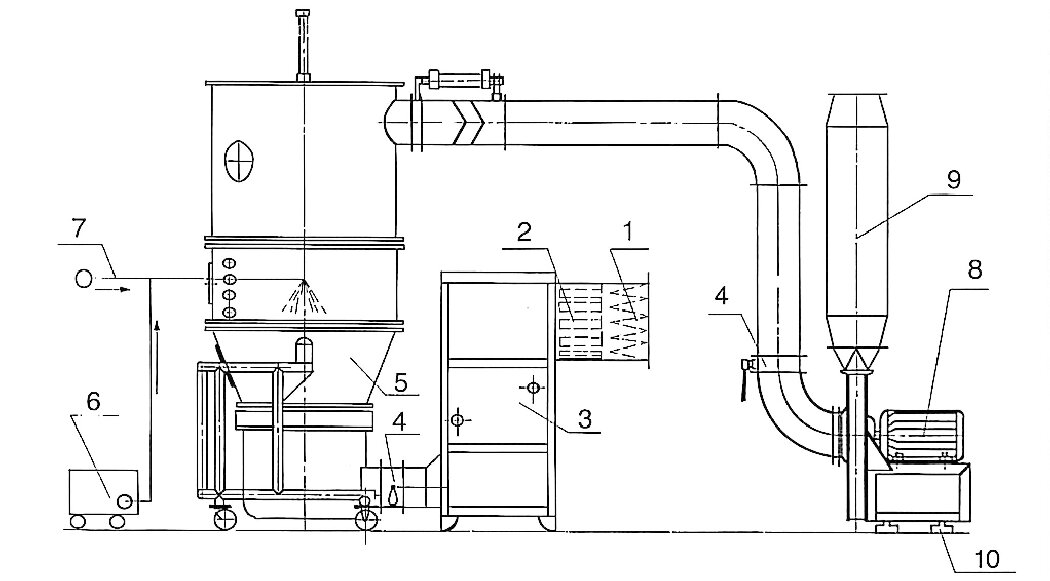

Process flow chart

1. Medium efficiency filter 2, sub high efficiency filter 3, heater 4, air regulating valve 5, fluidized bed 6, infusion pump 7, compressed air 8, induced draft fan 9, muffler 10, shock absorber

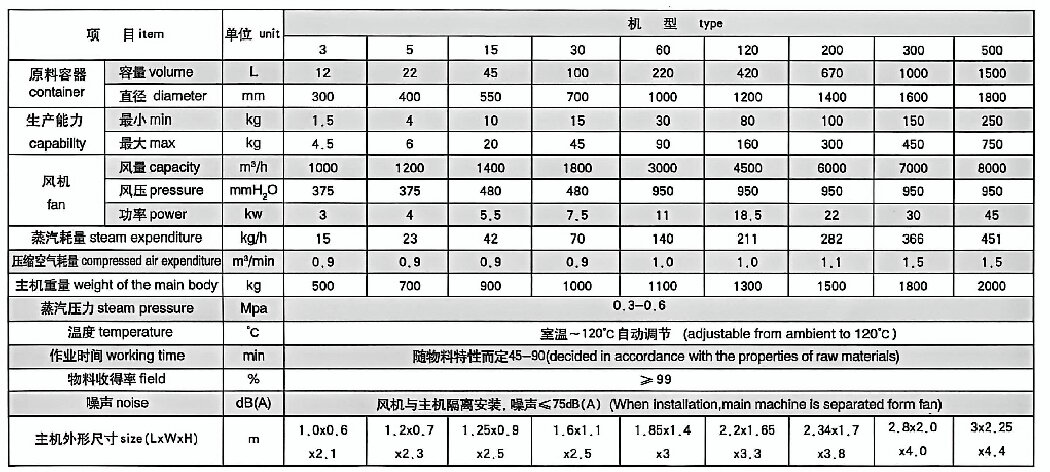

Technical specifications

Hot Tags: FL boiling granulation dryer Boiling granulation dryer Fluidized Bed Granulator dryer