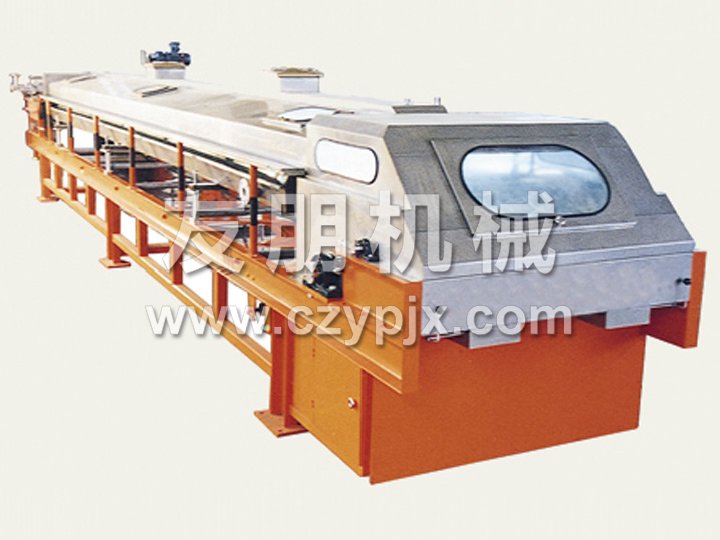

Equipment overview

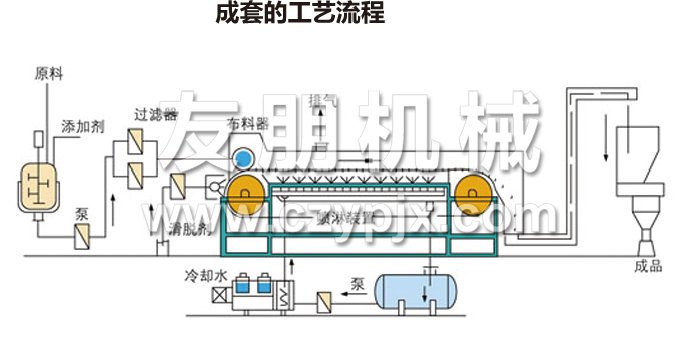

The RL series granulator is a new type of (melt-type) molding granulator that takes advantage of the material's melting point below 250°C and uses a special distribution device to evenly distribute the molten liquid to the steel belt moving below it according to the viscosity range of the material when it is in a molten state. A continuous spray device is installed below the steel belt to cool the steel belt. The material is cooled, shrunk, and solidified during transportation and movement on the steel belt, thereby achieving the purpose of making particles. Its working principle is to transform liquid materials into solids while transporting and cooling them through steel belts. It can granulate and shape materials with melting points ranging from 50°C to 300°C. The product molds quickly, has beautiful particles, is uniform in shape and nearly hemispherical, and has no thermal stress. Granular products are easy to package, transport and store, making it convenient for users to measure, mix or remelt. The production process is dust-free, improving the production environment, allowing continuous production from feeding to packaging, and reducing physical labor. It can realize stepless speed regulation, adjustable flow rate and easy operation. Widely used in petroleum, fine chemical and other industries.

Product features

◆ This product is a new type of (melt type) molding and granulating machine. It uses thin steel strips for heat transfer, and sprays atomized steel strips to quickly solidify the molten liquid on the steel strips.

◆ The single-machine rotating casing is easy to maintain, has little wear and tear, and has high production efficiency. Loading, unloading and product changeovers were quick.

◆ The forming machine operates synchronously with the steel belt to produce uniform particles at high speed, improving production efficiency and profits.

◆ It also eliminates dust, improves the environment and significantly expands the viscosity range.

◆ The production process of this product is economical and reliable, and can process Φ4-12mm particles. The particles are uniform, hemispherical, strip-shaped, and flake-shaped, stable, stress-free, high purity, and good quality.

◆ The equipment comes with filtering and interception devices, making its operation more reliable.

Structural features

◆ The machine is mainly composed of a granulation die that forms droplets, a cooling and conveying stainless steel belt, a pulley, a spray cooling system, a transmission system, a heat preservation device, a frame, a scraper, etc. The granulation die for droplet formation mainly consists of a die cover and a mandrel. The spray cooling system mainly consists of nozzles and liquid reservoirs. The transmission system mainly consists of a reduction gearbox (reducer) and a speed-regulating motor.

◆ Select the conveying speed and die speed according to the melting point (freezing point), liquid viscosity, and cooling effect to avoid affecting production capacity and particle quality.

◆ The liquid material is transformed into solid particles, mainly through the granulation die, using a continuously rotating steel belt, and is cooled by water spray to finalize the shape.

Applicable materials

This product is suitable for various materials that require granulating with a melting point (or softening point) of 50°C-300°C, as well as materials with "supercooling crystallization" characteristics.

Technical requirements

◆ Materials must be filtered to prevent solid impurities from entering the granulation die, causing wear or blockage and affecting the granulation quality.

◆ Temperature control should be based on the melting point temperature, and the temperature change should not exceed ±3°C to meet process requirements. The cooling system should have a filter, and the cooling water temperature should generally be between 5°C and 25°C (the lower the water temperature, the faster the molding, the better the particle quality, and the higher the output).

Process flow diagram

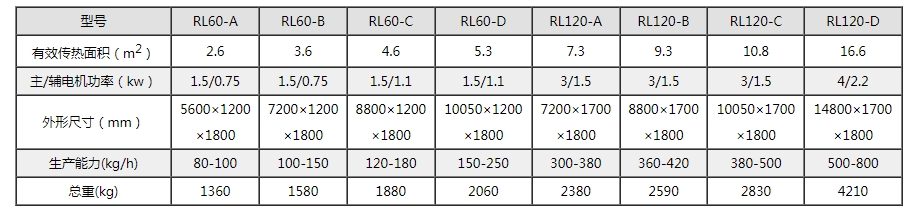

Model specifications

Hot Tags: Melting granulator RL melting pelletizer Melting pelletizer