The two-dimensional mixer is mainly composed of three parts: a rotary drum, a swing frame, and a frame. The drum is mounted on a swing frame, supported by four rollers and axially positioned by two gear wheels. Among the four supporting rollers, two transmission wheels are driven by a rotating power system to rotate the drum. The swing frame is driven by a set of crank swing rod mechanisms, which are mounted on the frame. The swing frame is supported on the frame by bearing components

view more

Changzhou Youpeng Machinery Co., Ltd

Our factory has over 20 years of experience in manufacturing equipment, with eight technical experienced R & D engineers and fifty-five skilled workers. We have introduced several sets of advanced production equipment, and digestion and absorption of advanced production technology, successfully acquired a number of patents, can provide customers with better service and products. The workshop area is over 6000 square meter; the office area is over 2000 square meter. And factory has certificated by BV, SGS, TUV and GMC. Factory production system have certificated by ISO9001-2008 & ISO14001-2004.

read more

DSH Double Spiral Cone Mixer is a new type of high-efficiency mixing equipment improved from the Single Spiral Cantilever Cone Mixer. The machine can be controlled by one (or two) sets of motors and reducers for self rotation and revolution, and adopts asymmetric mixing with two screws. The material mixing range is large and the mixing speed is fast. This machine is suitable for mixing materials such as powders and powders, as well as adding liquids to powders. It has strong adaptability to mixtures and does not mix heat sensitive materials.

view more

The LDH series plow blade mixer is a single axis forced mixing batch mixing equipment that can handle the mixing of solid powder and granular materials, and is suitable for liquid addition processes. The material is quickly crushed, cut, and dispersed under the strong shear force of the mixing plow blade and auxiliary flying blade, with excellent mixing effect.

view more

The horizontal screw belt mixer consists of a U-shaped cylinder, a stirring screw belt, and transmission components. Stirring screw belts are generally made into double layers. During operation, the outer layer of screw belts collects materials from both sides to the center, while the inner layer of screw belts pushes materials from the center to both sides, forming convective mixing. Spiral belt mixer is generally used for mixing viscous or cohesive granular materials, as well as mixing liquid or paste materials added to the granules.

view more

The drum dryer is an internally heated conductive rotary continuous drying equipment. The rotating drum is adhered to a thick film through its lower chute, and heat is transported to the inner wall of the drum through pipes, conducted to the outer wall of the drum, and then transmitted to the film, causing the moisture in the film to evaporate, dehumidify, and dry the material containing moisture. The dried material is scraped off the drum surface by a scraper and placed on the scraper

view more

A blade type dryer is a low-speed stirring dryer that is equipped with a stirring slurry inside the equipment, allowing wet materials to fully contact the heat carrier and hot surface under the stirring of the blades, thereby achieving the purpose of drying. The structural form is generally horizontal, double axis or four axis. The blade dryer is divided into hot air type and conduction type. Hot air type refers to the process of drying a material by contacting it with a heat carrier (such as hot air) and drying it

view more

ZPG Vacuum Rake Drying Machine is a novel horizontal intermittent vacuum drying equipment. Wet materials are evaporated through conduction, and a scraper stirrer is used to continuously remove the materials on the hot surface, forming a circulating flow in the container. After the water evaporates, it is pumped out by a vacuum pump. This machine adopts a large-area interlayer heating method, with a large heat transfer surface and high thermal efficiency. It is equipped with agitation to form a continuous circulation state of the material in the cylinder, further improving the quality of the material

view more

The working principle of the GFG series high-efficiency boiling dryer is that the air is heated and purified, and then introduced from the bottom by the induced draft fan, passing through the mesh plate of the hopper. In the studio, fluidization is formed through stirring and negative pressure, and the water evaporates rapidly and is carried away by the exhaust, resulting in rapid drying of the material.

view more

The centrifugal spray dryer is named for its centrifugal atomizer. It is one of the widely used drying equipment in industrial production. The machine operates by adding liquid to a high-speed rotating dispersion disk, where the liquid is flung into droplets by centrifugal force and then dried within the dryer. On the surface of the dispersion disk, the liquid spreads out into a thin film and is thrown out at high speed at the peripheral edge. The atomization effect depends on the atomizing disk...

view more

The circular vacuum oven stores materials in a cylindrical chamber for heating, while simultaneously using a vacuum pump to extract air and moisture. The drying process takes place under vacuum conditions, which significantly accelerates the drying rate of the materials. The circular vacuum oven is suitable for the drying of materials that require a higher vacuum degree.

view more

The double cone rotary vacuum dryer is an intermittently sealed drying equipment. During operation, the material is added into a closed container, and a heat source (such as hot water, low-pressure steam, or heat transfer oil) is introduced into the jacket of the container. The heat is conducted through the walls to heat the material. As the container is under vacuum conditions, the operating pressure drop causes the moisture (solvent) on the surface of the material to reach a saturated state and evaporate. The wet vapor is promptly expelled or recovered by a vacuum pump. The internal moisture of the material...

view more

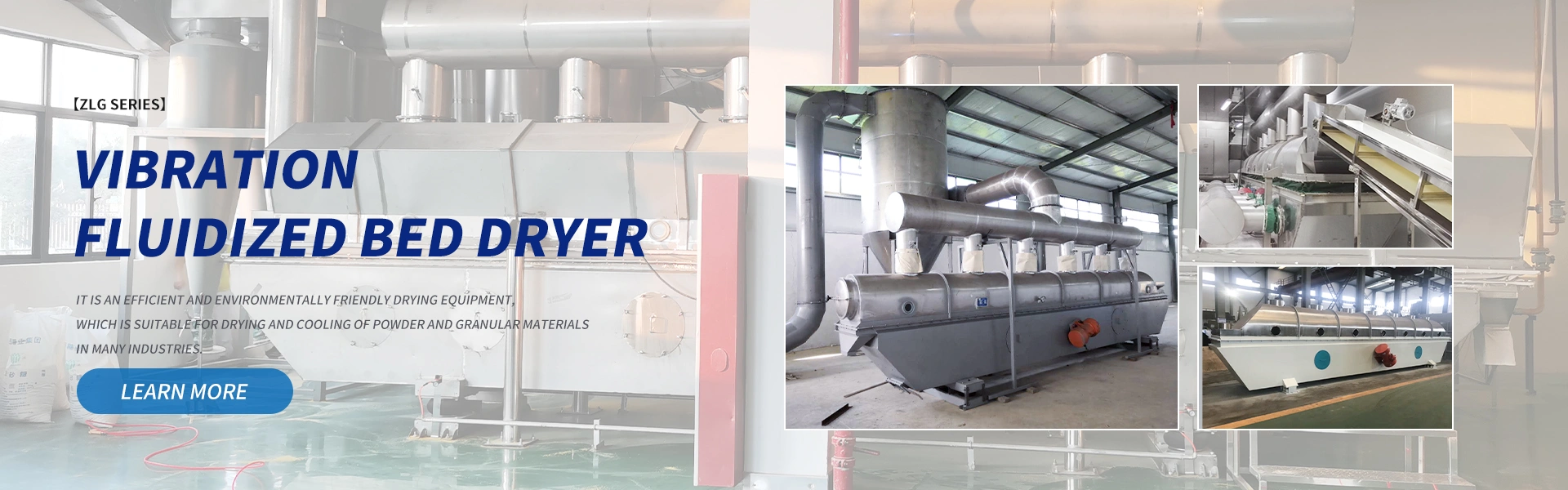

When the Vibrating Fluidized Bed Dryer operates, the material enters the dryer through the feed opening and, under the action of vibrational force and hot air, the material is tossed and jumps forward along the water bed surface. Hot air passes upward through the fluidized bed to fully exchange heat with the wet material, and the moist air, after dust removal by the cyclone separator, is exhausted by the exhaust fan. The dried material is discharged through the discharge outlet. This machine is suitable for the drying of powders in industries such as chemical, pharmaceutical, food, grain, and minerals.

view more