System overview

The closed-circuit spray drying system means that the drying medium circulates in a closed loop throughout the drying system, and uses inert gas instead of air as the drying medium. The inert gas is generally nitrogen. Inert gas can be recycled in the drying system and plays the role of heat transfer, moisture carrying and dehumidification. The drying system is often operated under positive pressure. If the internal pressure drops, the pressure transmitter can automatically control the entry of nitrogen to ensure the balance of the inert gas concentration in the system and control the oxygen content. The closed-circuit spray dryer is particularly suitable for drying materials containing organic solvents, as well as materials containing toxic gases or that are prone to oxidation during the drying process.

Working principle

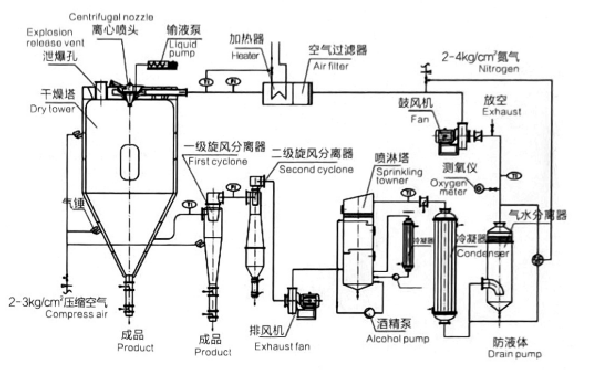

First, heated nitrogen is filled into the drying tower body and the air is discharged. The dried liquid material is transported to the atomizer through the infusion pump. The high-speed rotating centrifugal atomizer atomizes the material liquid into fine droplets. The droplets fully exchange heat with the hot nitrogen in the drying tower. The liquid solvent in the material is evaporated instantly. The dehumidified solid part forms a powdery material, which sinks to the bottom of the tower and is discharged. The drying time of the material is very short. Under the action of the fan, the evaporated organic solvent undergoes dust removal in the cyclone separator and then enters the condenser for condensation. The organic solvent gas is condensed into liquid and discharged from the condenser; the non-condensable gas (mainly nitrogen) is heated by the heater and sent to the dryer for recycling again.

Flow chart

System composition

The closed-circuit spray drying system mainly consists of a centrifugal spray dryer host, a gas filter, a heater, a blower, a first-level cyclone separator, a second-level cyclone separator, a condenser, a water and gas separator, an exhaust fan, a feed pump, an oxygen meter, as well as pipelines and control valve groups.

1. Feeding system

The feeding system consists of a mixing tank, a feeding pump, an atomizer, a feed liquid filter and connecting pipes. The liquid is stirred at low speed in the mixer to prevent it from settling, and is fed to the atomizer by the feeding pump. The mixing tank adopts an advanced design scheme, so that the slurry churns up and down without settling; the system is equipped with two stirring tanks, connected by pipe valves. After the feeding and transportation of one tank is completed, the valve switch is switched to connect to the other stirring tank to ensure continuous feeding

2. Dryer host

It is mainly composed of drying tower, cone bottom, manhole, vibrator, etc. The upper part of the drying tower is the hot air inlet and is equipped with a hot air distributor. The tower is operated with slight positive pressure to prevent outside air from infiltrating. The vibrator adopts PLC program control to vibrate the drying tower barrel wall at intervals to reduce material adsorption on the barrel wall and facilitate continuous production.

3. Collection system

It consists of cyclone separator, double-layer flap valve, cooling vibration table, etc. The dried product is collected by the double-layer flap valve at the cone bottom of the drying tower, and the cyclone separator assists in collecting the material. The cooling vibration table is a device specially used to cool the finished dry powder. Since the melting point of the finished product is low and the temperature at the exit of the drying tower is high, the material is still in a softened state. After this configuration, the material is fully cooled and meets the packaging requirements.

4.Recycling device

The recovery device is mainly composed of condenser and cooling system. The condenser can be a surface condenser or a mixing condenser. If a spray recovery device is used, the cooling medium is recycled solvent. After being cooled by the refrigerator, it is sprayed cyclically in the spray paint tower to recover the evaporated solvent.

5. Circulation fans and ventilation ducts

As the main component of the system, the circulating fan must ensure that it performs air supply and air induction tasks in a closed state. Sealed fans are used and are equipped with sealing devices to prevent the infiltration of outside air. The ventilation duct uses a quick-open connection clamp, and the contact part is made of soft polytetrafluoroethylene gasket, which is easy to disassemble without air leakage.

6. Online oxygen concentration analyzer

The analyzer mainly displays the oxygen concentration in the drying tower. Under normal circumstances, the oxygen concentration in the tower is set between 0.5% and 3%. If it exceeds the set value, automatic nitrogen supply can be started to keep the oxygen concentration within the set range. In addition, when the pressure in the tower exceeds the set value, the tower control valve automatically opens and closes automatically after the pressure reaches the set value. This instrument adopts automated programming interlock mode to ensure system safety.

7.Heating system

Steam heating can be used directly. If thermal oil heating is selected, the thermal oil furnace should be placed in a non-explosion-proof area. The high-temperature hot oil generated by the thermal oil furnace heats nitrogen through the radiator, and the heated nitrogen is sent to the drying tower by a blower. This heating method is the safest.

8.Control system

A programmable controller is used to control the operation of each device and fault alarm, imported intelligent instruments are used to control the temperature, Siemens electrical components are used to control the start and stop of each circuit, and an oxygen detection analyzer is used to control the oxygen concentration in the tower.

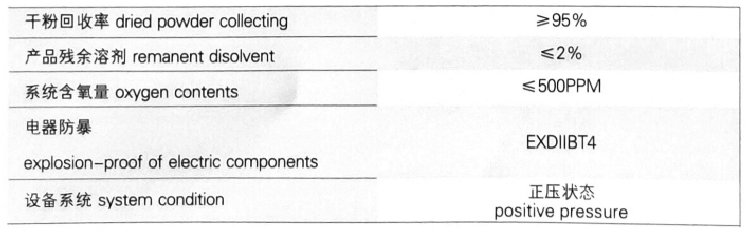

Technical parameters

Hot Tags: Closed cycle spray drying device Closed cycle spray drying Closed cycle drying device