Working principle

The system uses nitrogen with low moisture content as the drying medium, which has strong moisture carrying capacity. It is repeatedly used in the closed-circuit drying system and continues to undergo the process of moisture carrying and dehumidification until the wet material is dried. Under normal circumstances, when wet materials contain volatile organic solvents, or in environments that easily lead to dust explosions, inert gas nitrogen needs to be used as the drying medium. In the closed-circuit cycle drying process, the drying medium is heated by a heater, and the evaporated volatile matter is continuously condensed and turned into a liquid for collection. The drying medium from which the solvent vapor has been removed is reheated by the heater and then recycled. Due to the removal of liquid by condensation, the volatile content in the drying medium is very low. After reheating, its relative humidity will be further reduced. The drying medium has a strong moisture-carrying capacity, creating conditions for deep drying. This is why the nitrogen closed-circuit circulating fluidized bed drying system can effectively dry products to extremely low moisture content at lower operating temperatures. This type of fluidized bed drying equipment can also be called a boiling dryer.

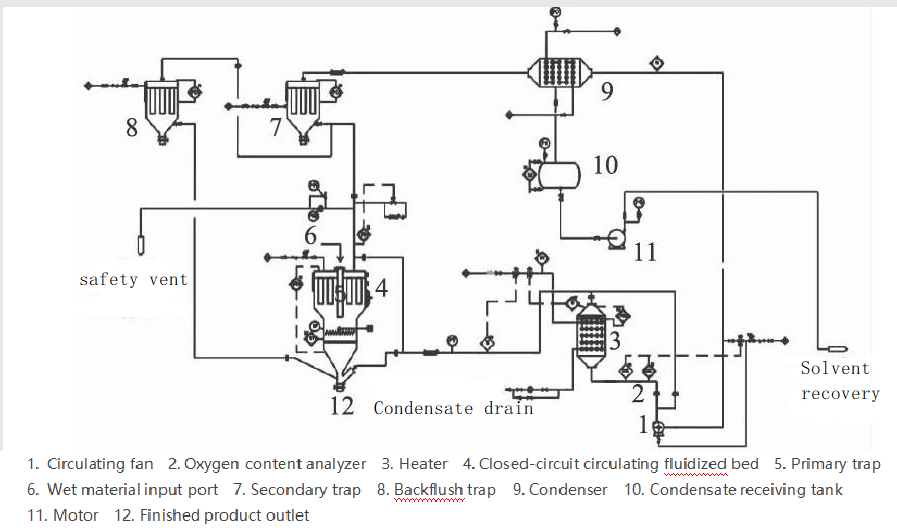

Process flow

Before starting drying, the equipment is first deoxidized and filled with nitrogen. At the same time, the fan is turned on, and the nitrogen is sent to the heater through the fan, and is heated by the heater and then sent to the dryer. In the large-area gas-solid two-phase contact, the moisture or solvent in the material evaporates quickly and is taken out with the exhaust gas to achieve the purpose of drying. The solvent is first dust-removed along with the exhaust gas at the bag (or filter barrel) of the top cylinder. After entering the dust collector, it is dusted for the second time (some equipment uses a cyclone separator for secondary dust removal and the bag is used for third-level dust removal). Then it enters the condenser from the dust collector. The solvent is cooled into liquid in the condenser and discharged from the condenser. The condensed gas is heated by the heater under the action of the fan and sent to the dryer again to complete the cycle.

Performance characteristics

1. Drying is completed under oxygen-free conditions, the material is not easily oxidized, denatured and degraded, and risks such as explosion and combustion are eliminated.

2. The temperature of the drying medium does not need to be very high, but it has strong moisture carrying capacity and can deeply dry the materials. The final moisture content of the finished product can reach 0.02% to 0.1%.

3. All solvents can be recycled, greatly reducing product costs.

4. The drying rate is fast, the production capacity is greatly improved, and large-scale production can be achieved.

5. The dryer and the collector are integrated into one, so that the shape, color, moisture content, etc. of the dried products are uniform and the quality is stable. Subsequent processes such as product mixing, compounding and cooling can also be completed in the same equipment without moisture absorption.

6. According to the technical characteristics of closed-circuit circulation drying, continuous feeding can be used for drying, which greatly improves the drying efficiency.

7. Due to closed-circuit operation, no waste gas and dust are discharged into the atmosphere, which will not cause environmental pollution. The company has a good production environment and low labor intensity for employees.

Application scope

In modern industrial production, especially in petrochemical, fine chemical, pharmaceutical, pesticide, intermediate, bioengineering and other industries, there are many special materials that are sensitive to heat, contain flammable and explosive solvents, and are easily hygroscopic and denatured when exposed to the air. Their heat resistance is very poor, but they have strict requirements on the moisture content of the dried product (for example, it needs to be controlled below 0.1%), and they also require uniform drying of the product, which brings difficulties to the drying operation. Nitrogen closed-circuit circulating fluidized bed drying can solve this problem well. It has the advantages of high drying rate, good product quality, recyclable solvent, safety, and environmental protection. It can also recover a large amount of heat in the dry exhaust gas and save a large amount of cold energy used to cool the dry exhaust gas. The energy saving effect is significant and it has broad application prospects.

Hot Tags: Closed circuit circulating fluidized bed drying device Closed circuit circulating fluidized bed drying Fluidized bed closed loop drying