-

Closed cycle spray dryerThe closed-circuit spray drying system means that the drying medium circulates in a closed loop throughout the drying system, and uses inert gas instead of air as the drying medium. The inert gas is generally nitrogen. Inert gas can be recycled in the drying system and plays the role of heat transfer, moisture carrying and dehumidification. The drying system is often operated under positive pressure. If the internal pressure drops, the pressure transmitter can automatically control the entry of nitrogen to ensure the balance of the inert gas concentration in the system and control the oxygen content. The closed-circuit spray dryer is particularly suitable for drying materials containing organic solvents, as well as materials containing toxic gases or that are prone to oxidation during the drying process.read more

-

Closed circuit circulating fluidized bed drying systemClosed-circuit circulating fluidized bed drying can well solve the drying problem of special materials. In modern industries, such as petrochemicals, fine chemicals, pharmaceuticals, pesticides, intermediates, bioengineering and other industries, there are many special materials that are sensitive to heat, or contain flammable and explosive solvents, or are prone to hygroscopic degeneration when exposed to the air. Their heat resistance is very poor, but the moisture content of the dried products is very strict (for example, it needs to be controlled below 0.1%), and the products are required to be dried evenly. This equipment has the advantages of high drying rate, good product quality, solvent recyclability, safety, and environmental protection.read more

-

Single effect concentrating evaporatorA single-effect evaporator generally refers to a single independent evaporator. The secondary steam generated when evaporating a solution is no longer used, and is suitable for the evaporation of small-scale solutions. Single-effect evaporators rarely use intermittent evaporation. Common operating modes include semi-intermittent evaporation, continuous batch evaporation, continuous evaporation, etc.read more

-

Double-effect evaporation and concentration systemDouble-effect evaporator, also known as second-effect evaporator, usually uses the secondary steam generated by the first evaporator as a heating source again and introduces it into another evaporator. As long as the pressure and boiling point of the solution in the evaporator are controlled to appropriately reduce them, the secondary steam generated by the first evaporator can be used for heating. The secondary steam condensation point of the first evaporator is the heating point of the second evaporator. This is the principle of double-effect evaporation. Generally speaking: single-effect evaporation consumes 1.1~1.2 tons of steam per ton of water, and double-effect evaporation consumes 0.6~0.7 tons of steam per ton of water.read more

-

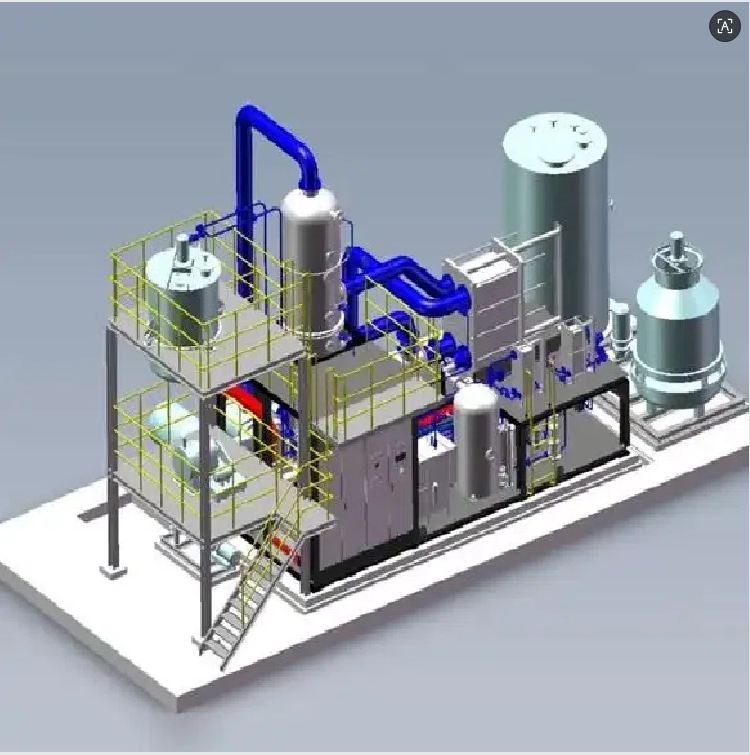

MVR evaporation concentration systemMVR evaporator is a new type of equipment that has attracted much attention in the field of evaporation and concentration in recent years and has demonstrated significant industry advantages. It consumes electrical energy or other forms of mechanical energy as the main energy source. Compared with traditional evaporators, it greatly reduces the consumption of raw steam, greatly reduces operating costs, and effectively saves the company's production costs. At the same time, the equipment is compactly arranged, occupies a small area, and consumes less circulating water, which greatly saves land and water resources. In addition, the system can achieve low-temperature operation, is suitable for evaporation and concentration of heat-sensitive materials, retains material quality to a large extent, and is widely used for specific materials in pharmaceuticals and food processing.read more

-

WLDH series horizontal screw belt mixerThe horizontal screw belt mixer consists of a U-shaped cylinder, a stirring screw belt, and transmission components. Stirring screw belts are generally made into double layers. During operation, the outer layer of screw belts collects materials from both sides to the center, while the inner layer of screw belts pushes materials from the center to both sides, forming convective mixing. Spiral belt mixer is generally used for mixing viscous or cohesive granular materials, as well as mixing liquid or paste materials added to the granules.read more

-

CH series slot mixerThe CH series trough mixer is used to mix powdered or wet materials, ensuring uniform mixing of different proportions of main and auxiliary materials. The contact area between the machine and the material is made of stainless steel, with a small gap between the blade and the barrel, and no dead corners in the mixing process. The mixing shaft is equipped with sealing devices at both ends to prevent the material from spilling out. The hopper is controlled by a button jog, making it easy to discharge. Widely applicable to industries such as pharmaceuticals, chemicals, and food.read more

-

WZ series gravity free mixerThe WZ series gravity free mixer is composed of a horizontal cylinder, a double blade mixing shaft, and a transmission mechanism. It has strong mixing force and can achieve rapid mixing in a short period of time. It is particularly skilled in handling the mixing of materials with significant differences in physical properties such as density, fineness, and flowability. It is mainly used in fields such as electronic batteries, building mortar, environmental protection, mining, and agriculture, and is suitable for powders, particles, fibers, and other materialsread more

-

LDH series plow blade mixerThe LDH series plow blade mixer is a single axis forced mixing batch mixing equipment that can handle the mixing of solid powder and granular materials, and is suitable for liquid addition processes. The material is quickly crushed, cut, and dispersed under the strong shear force of the mixing plow blade and auxiliary flying blade, with excellent mixing effect.read more

-

WH series double helix cone mixerDSH Double Spiral Cone Mixer is a new type of high-efficiency mixing equipment improved from the Single Spiral Cantilever Cone Mixer. The machine can be controlled by one (or two) sets of motors and reducers for self rotation and revolution, and adopts asymmetric mixing with two screws. The material mixing range is large and the mixing speed is fast. This machine is suitable for mixing materials such as powders and powders, as well as adding liquids to powders. It has strong adaptability to mixtures and does not mix heat sensitive materials.read more

-

SZH series double cone mixerThe SZH series double cone mixer transfers powder or granular materials into a double cone container through vacuum conveying or manual feeding. As the capacity continues to rotate, the materials undergo complex impact movements in the container to achieve uniform mixing. This machine is energy-saving, easy to operate, has low labor intensity, and high work efficiency. This machine is suitable for mixing powdered and granular materials in industries such as pharmaceuticals, chemicals, food, and building materials.read more