Drying Equipment

-

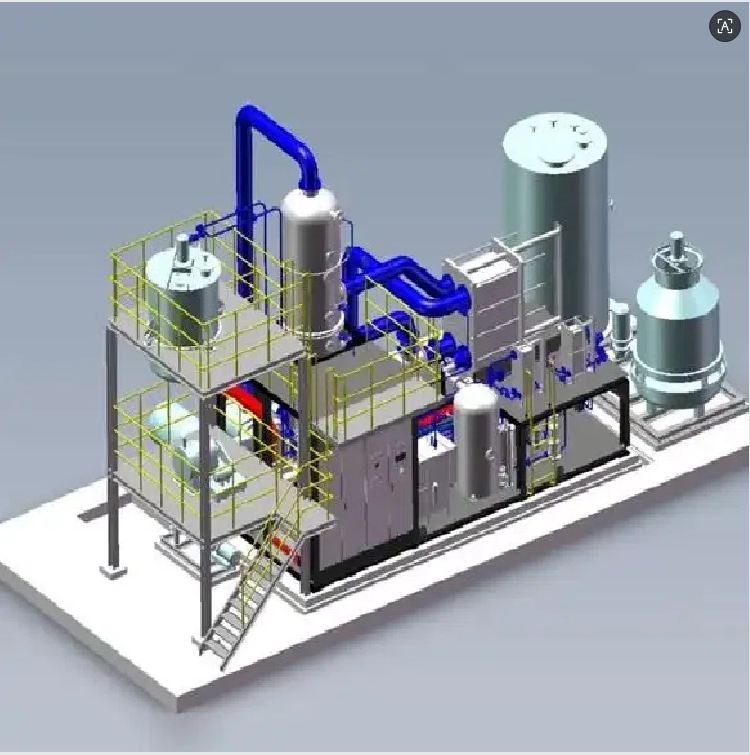

Closed circuit circulating fluidized bed drying systemClosed-circuit circulating fluidized bed drying can well solve the drying problem of special materials. In modern industries, such as petrochemicals, fine chemicals, pharmaceuticals, pesticides, intermediates, bioengineering and other industries, there are many special materials that are sensitive to heat, or contain flammable and explosive solvents, or are prone to hygroscopic degeneration when exposed to the air. Their heat resistance is very poor, but the moisture content of the dried products is very strict (for example, it needs to be controlled below 0.1%), and the products are required to be dried evenly. This equipment has the advantages of high drying rate, good product quality, solvent recyclability, safety, and environmental protection.read more

-

Single effect concentrating evaporatorA single-effect evaporator generally refers to a single independent evaporator. The secondary steam generated when evaporating a solution is no longer used, and is suitable for the evaporation of small-scale solutions. Single-effect evaporators rarely use intermittent evaporation. Common operating modes include semi-intermittent evaporation, continuous batch evaporation, continuous evaporation, etc.read more

-

Double-effect evaporation and concentration systemDouble-effect evaporator, also known as second-effect evaporator, usually uses the secondary steam generated by the first evaporator as a heating source again and introduces it into another evaporator. As long as the pressure and boiling point of the solution in the evaporator are controlled to appropriately reduce them, the secondary steam generated by the first evaporator can be used for heating. The secondary steam condensation point of the first evaporator is the heating point of the second evaporator. This is the principle of double-effect evaporation. Generally speaking: single-effect evaporation consumes 1.1~1.2 tons of steam per ton of water, and double-effect evaporation consumes 0.6~0.7 tons of steam per ton of water.read more

-

MVR evaporation concentration systemMVR evaporator is a new type of equipment that has attracted much attention in the field of evaporation and concentration in recent years and has demonstrated significant industry advantages. It consumes electrical energy or other forms of mechanical energy as the main energy source. Compared with traditional evaporators, it greatly reduces the consumption of raw steam, greatly reduces operating costs, and effectively saves the company's production costs. At the same time, the equipment is compactly arranged, occupies a small area, and consumes less circulating water, which greatly saves land and water resources. In addition, the system can achieve low-temperature operation, is suitable for evaporation and concentration of heat-sensitive materials, retains material quality to a large extent, and is widely used for specific materials in pharmaceuticals and food processing.read more

-

GFG high-efficiency boiling dryerThe working principle of the GFG series high-efficiency boiling dryer is as follows: After the air is purified and heated, it is drawn into the bottom of the hopper by an induced draft fan and passes through the bottom grid plate of the hopper. In the working chamber, fluidization is formed through stirring and negative pressure. Moisture evaporates quickly and is discharged, thereby enabling rapid drying of the material.read more

-

MPG inert particle fluidized bed drying machineInert particle fluidized bed drying can replace spray drying in many occasions, and is suitable for drying solution materials. Compared with spray drying, it has higher drying intensity and can be dried with lower heat source temperature (such as low-pressure steam, waste hot water, etc.); Under the same conditions, the equipment scale is much smaller (its volume is generally only about 10% of that of the spray drying tower), the system floor area and height are significantly reduced, and the equipment investment is relatively low...read more