Drying Equipment

-

CT-C hot air circulation ovenThe CT-C series hot air circulation oven is equipped with a low-noise and high-temperature resistant axial flow fan and an automatic temperature control system. The entire circulation system is fully enclosed, which increases the thermal efficiency of the oven from the traditional drying room 3-7% to the current 35-45%, and the high thermal efficiency can reach 50%. The successful design of CT-C type hot air circulation oven has enabled China's hot air circulation oven to reach domestic and international standards.read more

-

GMP medicinal ovenThe medicinal GMP oven has three heating sources: steam, electricity, and dual-purpose electric steam. The temperature is automatically controlled and recorded by a recorder; The inner walls of the box are fully welded, and various transition points are rounded with no dead corners. The whole machine has good sealing performance, and the unique guide rail sealing device ensures the sealing performance of the whole machine; The air inlet is equipped with a high-efficiency air filter; The dehumidification outlet is equipped with a medium efficiency air filter.read more

-

XSG series rotary flash dryerThe XSG series of rotary flash dryers are technologically advanced, compact in design, easy to operate, and convenient for maintenance. They enhance the heat transfer between gas and solid, significantly reducing drying time and greatly improving both product yield and quality, with very noticeable energy-saving effects.read more

-

QG series airflow dryerAirflow drying is a batch-type, high-heat-efficiency rapid continuous instantaneous drying equipment. Wet materials enter the dryer together with the conveying device and heated air. The two are fully mixed, and due to the large heat and mass transfer area, the purpose of evaporation drying can be achieved in a very short time. The dried finished product is discharged from the cyclone separator, and a small part of the material is recovered and reused from the cyclone separator or bag dust collector. Over the years, through continuous improvement and upgrading, it has developed into four series: Q series (basic type), QG series pulse airflow type, FG series exhaust gas circulation type, and JG series intensified crushing type.read more

-

XF series horizontal boiling dryerBoiling drying, also known as fluidized bed drying, mainly consists of an air filter, heater, boiling bed main unit, cyclone separator, bag dust collector, high-pressure centrifugal fan, and control panel. Depending on the nature of the raw materials, dust removal equipment can be配套 used. Cyclone separators and bag dust collectors can be selected for dust removal, or one of them can be used alone.read more

-

ZLG series vibrating fluidized bed dryerThe vibrating fluidized bed dryer generates excitation force through the vibration source, making the material easier to fluidize. The material enters the dryer, and under the action of vibration force and hot air, the material is thrown up and jumps forward along the surface of the fluidized bed. The hot air passes through the fluidized bed to fully exchange heat with the moist material. Then it is dusted by a cyclone separator or bag dust collector and then discharged by an exhaust fan. The dried material is discharged from the discharge port at the other end of the fluidized bed. This machine is suitable for powder drying in chemical, pharmaceutical, food processing, grain, mineral and other industries.read more

-

LZG series spiral vibration dryerDrying method of spiral vibrating dryer: Wet materials enter the spiral bed from the top feeding port. Under the action of circumferential exciting force and gravity, the materials jump down along the spiral bed from top to bottom until they reach the bottom layer. Meanwhile, clean hot air enters from the bottom of the spiral bed, undergoes sufficient heat and mass transfer with the raw materials distributed on the bed, and then is discharged through the top moisture exhaust port, thus achieving the purpose of material drying.read more

-

KJG hollow blade dryerA paddle dryer is a low-speed mixing drying equipment. It is equipped with mixing paddles inside, and wet materials are fully contacted with the heating surface of the heat carrier under the stirring of the paddles, thereby achieving the drying purpose. Its structural form is generally horizontal, adopting a dual-shaft structure. Paddle dryers can be divided into hot air type and conductive type. The hot air type is a drying process in which the material is directly contacted with the heat carrier (such as hot air).read more

-

HG rotary drum scraper dryerA rotary drum scraper dryer is a continuous drying device with internal heating conduction. The rotating drum adheres to a liquid film through a trough at its lower part. Heat is transmitted via pipes to the inner wall of the drum, then conducted to the outer wall, and subsequently transferred to the liquid film on the outer wall. This causes the moisture in the film to evaporate and dehydrate, thereby achieving the purpose of drying the material. After drying, the material is scraped off the surface of the drum by a scraper and discharged from the machine.read more

-

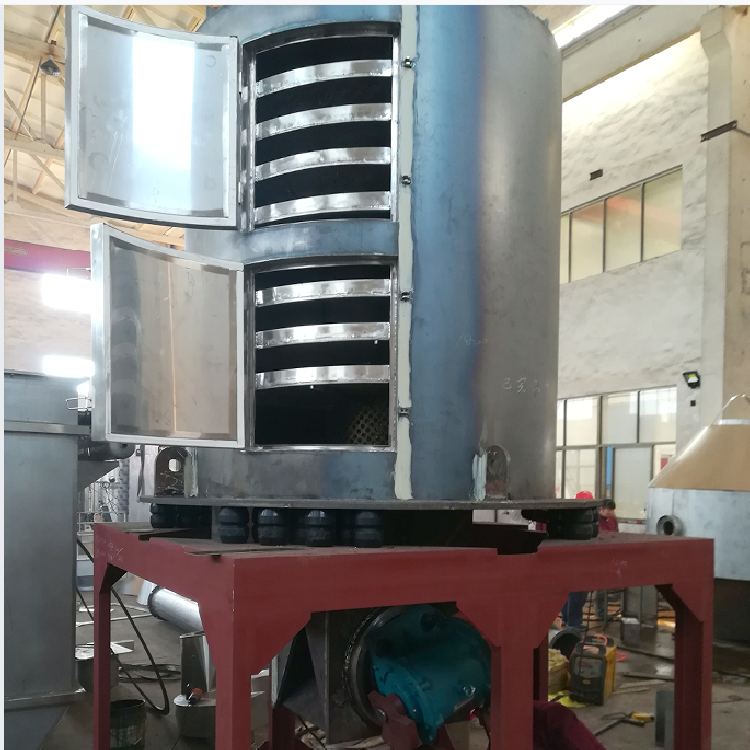

PLG series disc continuous dryerThe PLG series plate dryer is a continuous drying equipment mainly based on heat conduction, which is improved and developed from intermittent stirring conduction drying. It consists of multiple layers of fixed hollow heating circular material-carrying discs, a rotating shaft, stirring paddles, and an externally vertically fixed cylindrical body. The heat carrier is introduced into the hollow discs, indirectly heating the wet material on the surface of the discs through heat conduction. The rotating paddles continuously flip and scrape the material to achieve the purpose of rapid drying.read more

-

LPG series centrifugal spray dryerThe centrifugal spray dryer is named for its use of a centrifugal atomizer and is one of the widely used drying equipment in industrial production. The working principle of this machine is to add liquid to a high-speed rotating dispersing disc, where the liquid is flung into droplets under the action of centrifugal force, and then dried inside the dryer. On the surface of the dispersing disc, the liquid spreads into a thin film and is ejected at high speed from the edge. The atomization effect depends on the atomizing disc...read more

-

TCM extract spray dryerThe high-speed centrifugal spray drying unit for Chinese herbal medicine extracts is an application of centrifugal spray drying technology in the drying of specific materials. It uses a high-speed centrifugal atomizer to disperse the material into a mist, which then fully contacts hot air to complete instant drying, forming a powder product. The dedicated spray dryer for Chinese herbal medicine extracts is a spray dryer specifically designed to solve the spray drying problems of Chinese herbal medicine extracts and plant extracts.read more